Read on to learn more about butane collection for true boiling point distillation. Butane is a component of crude oil that boils well below room temperature. Its low boiling point requires special receivers to prevent the loss of butane from the system. Dry ice or a cold finger-style cooling system cools the receivers. Vapor Temperature Changes […]

Vacuum Pot Still (VPS) The vacuum pot still distills crude oil residue from 370 ºC up to 565 ºC. D5236 is the ASTM test number. It is most commonly used to distill the residue from ASTM D2892 true boiling point test. There are four sizes of distillation column shown in the table below with corresponding […]

Lab-scale Crude Oil Distillation Distillation of crude oil in the laboratory models what happens in the refinery. The results of the lab-scale distillation predicts the quantity and quality of each distilled product from the refinery. This information is used to choose the best crude oils for a refinery at the best price. The refinery distills […]

True boiling point distillation has distillation column packing that has 15 theoretical plates of efficiency. Many different types of packing are currently available. There are two main categories of packing. Structured and random packing. Pro-Pak The most popular type of distillation column packing used is called Pro-Pak. Pro-Pak is made by the Cannon Instrument Company. […]

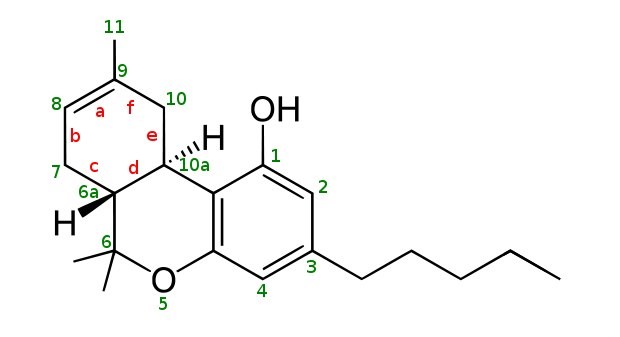

THC Oxidation to CBN CBN is the oxidative degradation product of THC. It is more stable than THC due to its conjugated structure. THC- Delta 9 CBN […]

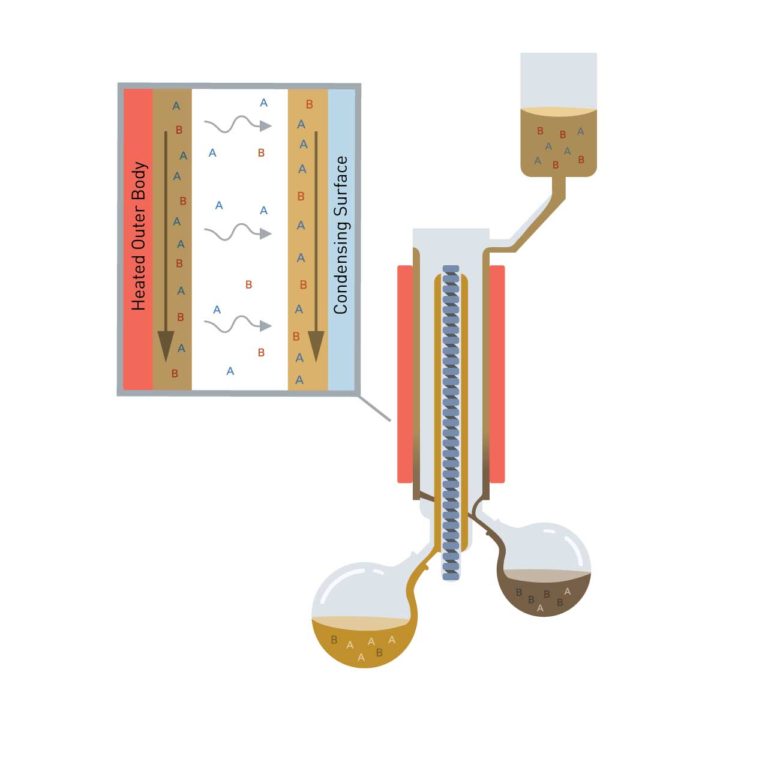

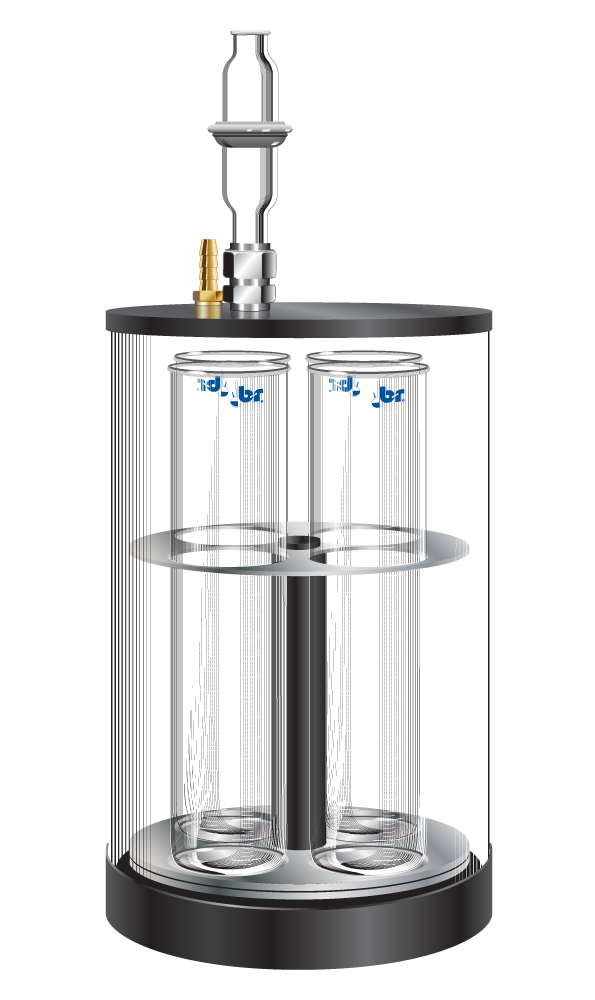

Spinning Band Distillation Spinning band distillation offers a high efficiency distillation column that can produce 90+% cannabinoid distillate in a single pass. A single pass distillation means you’ll spend a lot less time distilling. Operation is streamlined. The spinning band acts as dynamic packing. Condensed oils are pumped back down the column while pure vapors rise […]

Spinning band distillation separates the cannabis oil extract according to the boiling points of the components. Mono-terpenes have the lowest boiling points, so they are collected first. They can be found in the cold trap receiver due to their low boiling points. Residual ethanol is collected next in the fraction collector followed by the higher […]

Those “things” near bottom of the spinning band distillation column are called bellows. They function as a flexible expansion joint. Glass is normally anything but flexible and these bellows are engineered to allow the expansion and contraction over the length of the column. Distillations start at room temperature and goes up to the distillation temperature […]

The spinning band distillation column has a vacuum jacket (like a thermos) to minimize heat loss through the distillation column wall. The evacuated jacket disrupts heat conduction due to the lack of air (only 10-7 mmHg !). The vacuum jacket has a silver coating on the inside to reflect any radiant heat. Combined with the […]

Spinning band distillation Spinning band distillation can produce distillate with very high THC/CBD concentrations. Over 90% THC concentration is typical for a first pass. Some customers are routinely producing 98%+ cannabinoid distillates! How does the spinning band do it? Distillation separates components by their boiling points. This is commonly referred to as the “efficiency” of […]

Latest Blog Posts

Instant THC and CBD Potency in Edibles by Near Infrared (NIR)

by Paul on August 14, 2021

B/R Solvent Recyclers, Safe Recycling since 1986

by Paul on August 9, 2021

Touch Screen Makes Solvent Recycling Easier

by Paul on August 8, 2021

Measure THC, CBD and more in Real Time During CO2 Extraction with Near Infrared

by Paul on August 7, 2021

SCB-15 THC Remediation Case Study

by Paul on July 14, 2021

Questions?

Contact us for more information on our products and services.