Solvent Recycling just got easier with B/R’s touch screen ProCycler and MiniProCycler units. Read on to see how we have implemented the latest technology to improve safety, troubleshooting, and operator experience.

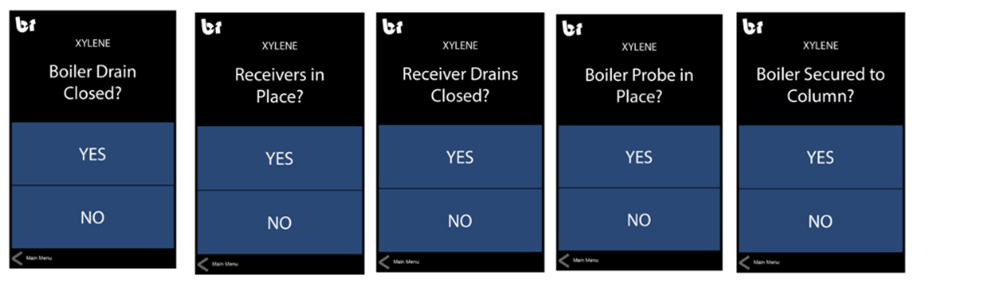

Safety Reminders

When starting a solvent recycling batch, the operator is prompted with safety reminders that ensure the distillation system is correctly configured. The operator must confirm each safety question before recycling can begin, which improves safety, especially for new operators or those who haven’t run the recycler for a while. The large touch screen makes the safety questions hard to miss.

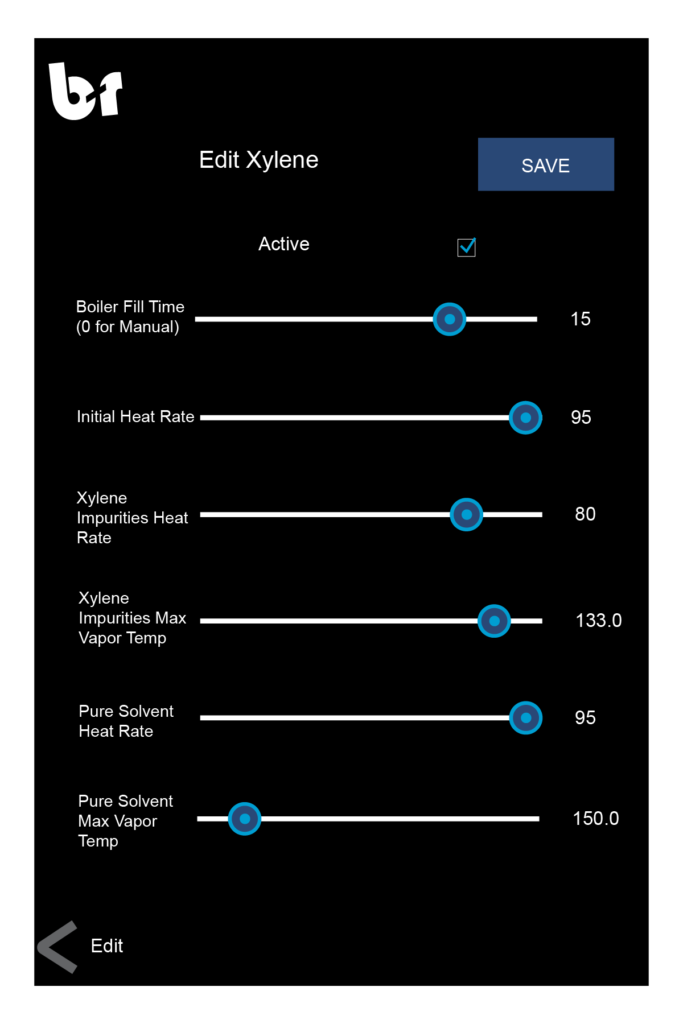

Recycling Programs

Your B/R solvent recycler comes preprogrammed with recycling programs for common histology solvents. Recycling programs can be edited to optimize them for your specific waste solvent. Slider bars allow easy adjustment of fill time, heating rates, fraction temperatures, and maximum boiler temperature. Just hit save when finished. Need to remove a particular solvent from the start menu? Just un-click the “Active” check box and the solvent will be removed from the start up menu.

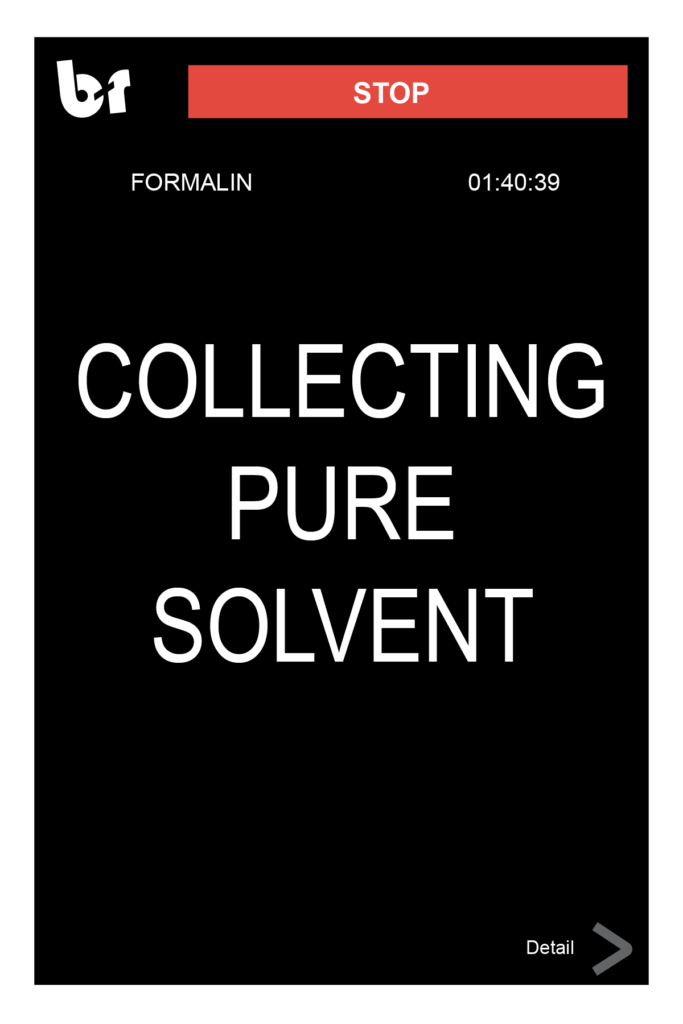

View Current Recycler Status

With the ProCycler and MiniProCycler units, you can view the current recycler status while recycling. You can also see the solvent being recycled (Formalin, Xylene, Alcohol, Xylene Substitute) along with the material that is currently being collected (Pure Solvent or Impurities Being Removed).

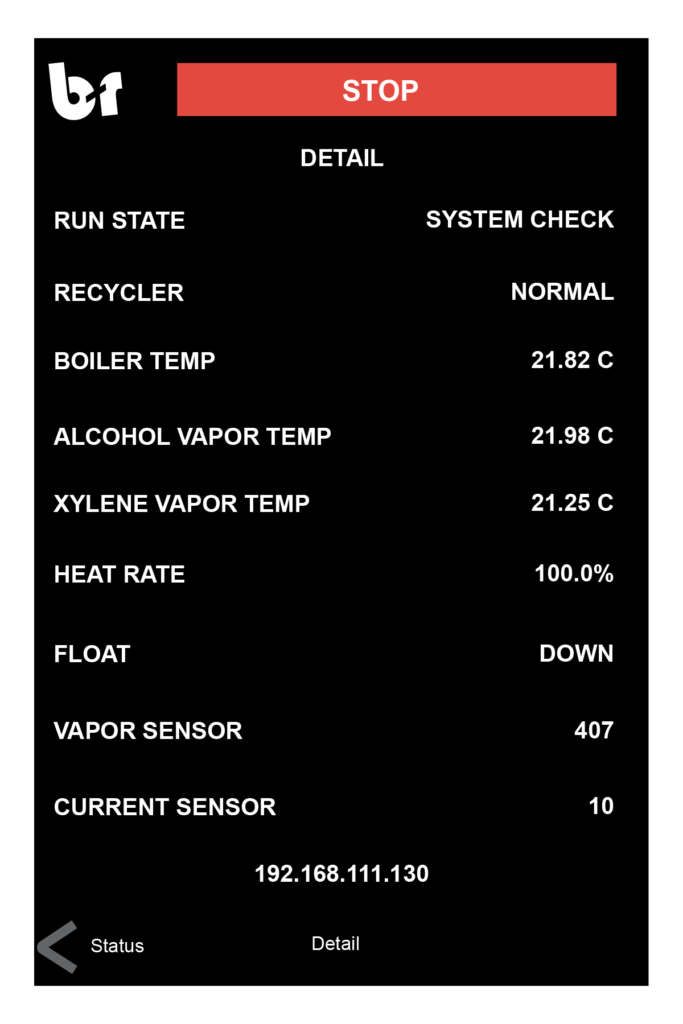

See Current Temperatures and Sensor Outputs

You can easily view current system details in the “Details” screen, including boiler and vapor temperatures, current heat rate, vapor, current sensor output, and overfill float position. This is great for troubleshooting or even just for general interest.

See How the Last Recycling Run Ended

The recycler keeps a record of how the last recycling run ended, whether that means the unit reached max boiler temperature, reached max vapor temperature, the operator aborted the run, or there was some other error. This information can drastically simplify troubleshooting if the operator suspects any problems.

Connect to WiFi or Ethernet for Remote Diagnostics

B/R can remotely access each controller to perform diagnostics if needed, using the Ethernet and Wifi built in to each recycler controller. All you need to do is connect to the internet and send us the IP address shown on the touch screen so that we can remotely access the controller. If the internet is not available, remove the SD card and put in a PC connected to the internet so that we can remotely access the logs on the SD card for diagnostics.

Learn More

Contact B/R today to learn how our touch screen units can make solvent recycling easier.

Leave a Reply