What’s the best way to measure THC, CBD, and more in real-time during CO2 extraction? The answer is Near Infrared.

Save Time and Money with Near Infrared (NIR)

Finding the best-operating conditions for your extractor can be a slow process. Extracting CO2 from cannabis presents some unique challenges – specifically with THC-a. How do you know when to stop extracting?

Instead of extracting periodically and sampling for HPLC analysis, which is time-consuming and labor-intensive, you can use Near Infrared (NIR) to continuously monitor the concentrations of:

- THC

- THC-a

- CBD

- CBD-a

- Minor Cannabinoids

- Total Cannabinoids

- Fats/Waxes

- Terpenes

- Ethanol

Monitor Ethanol Concentration During CO2 Extraction

Sometimes ethanol is used to aid in the extraction of THC-a during CO2 extraction. Some systems that bleed in the ethanol are rudimentary, and there is no way to confirm if the correct amount of ethanol is being added or not. NIR can monitor the ethanol concentration to ensure that the concentration is correct and constant.

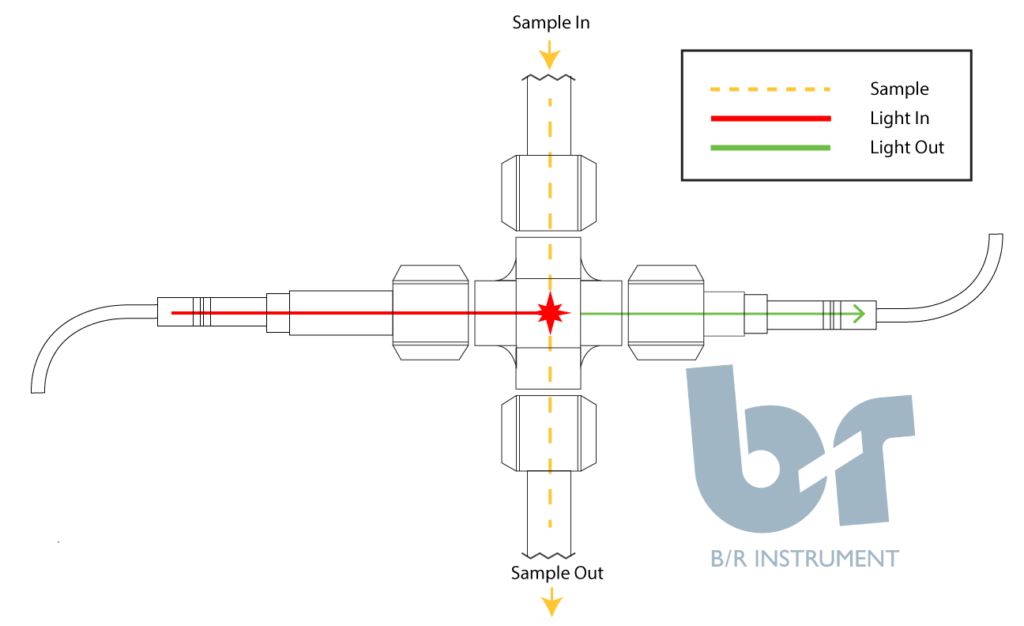

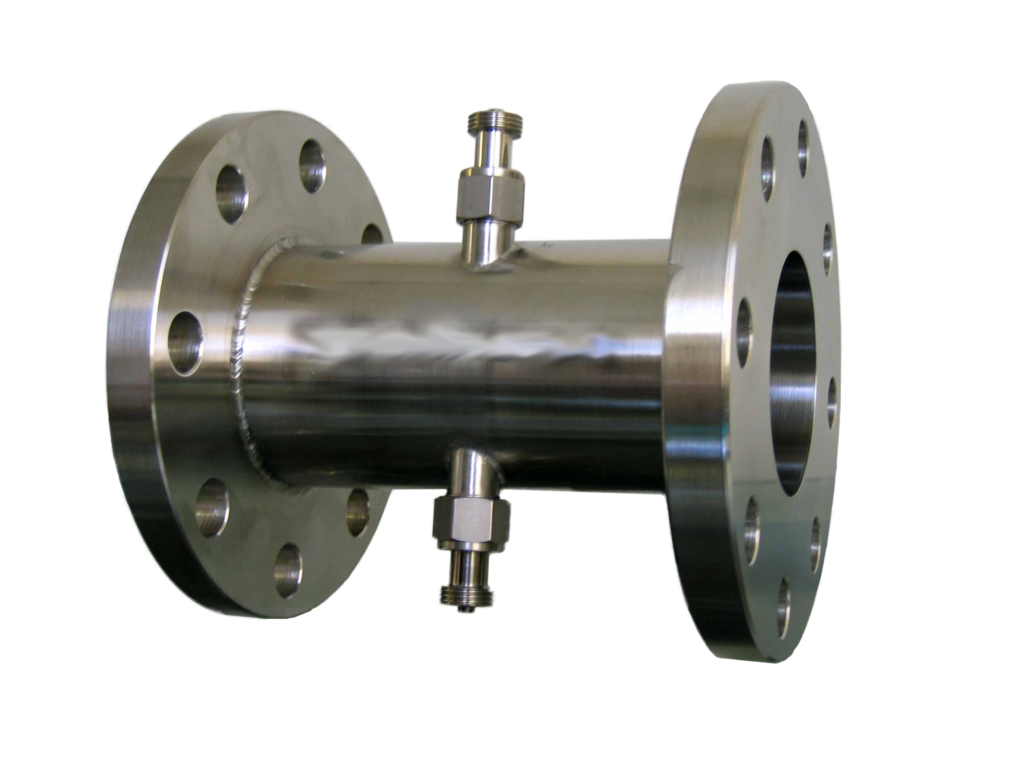

NIR Flow Cell Sensor

A NIR sensor can be installed into a flow cell, which allows users to take measurements as the CO2 and extract flow through piping from the extractor. The NIR flow cells are rated up to 2,500 PSI, which is well within the pressures used in CO2 extractors.

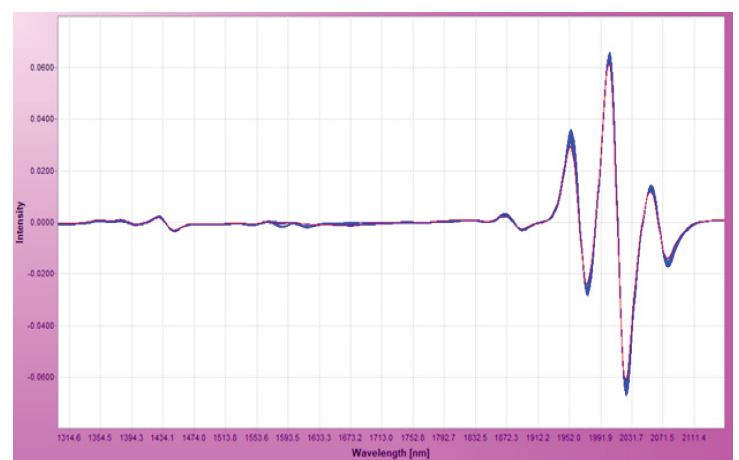

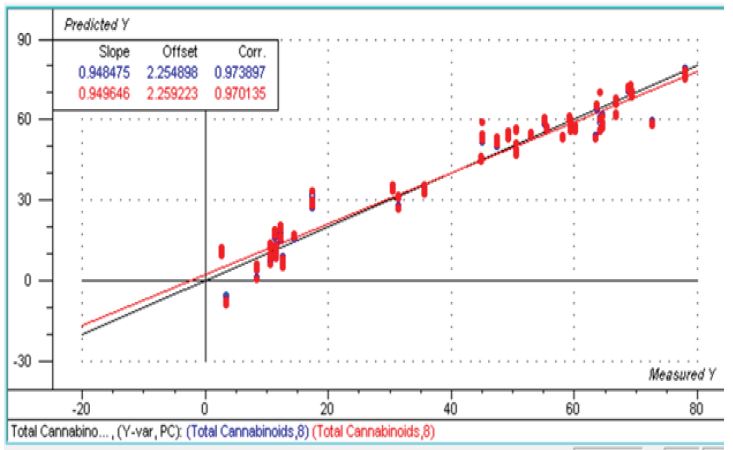

How does Near Infrared measure cannabinoids?

Wavelengths in the Near IR are beamed into the extract during extraction. A detector measures the response of the material to the various wavelengths of Near IR, and then compares this to a calibration model. This produces a real-time measurement of THC, THCa, CBD, CBDa, and other cannabinoids.

Learn More

Contact B/R today to learn more about you can use Near Infrared to measure THC, CBD and more in real-time During CO2 Extraction.

November 23, 2021 at 7:21 pm

interested in this