No Leaks – No Streaks – No Smell

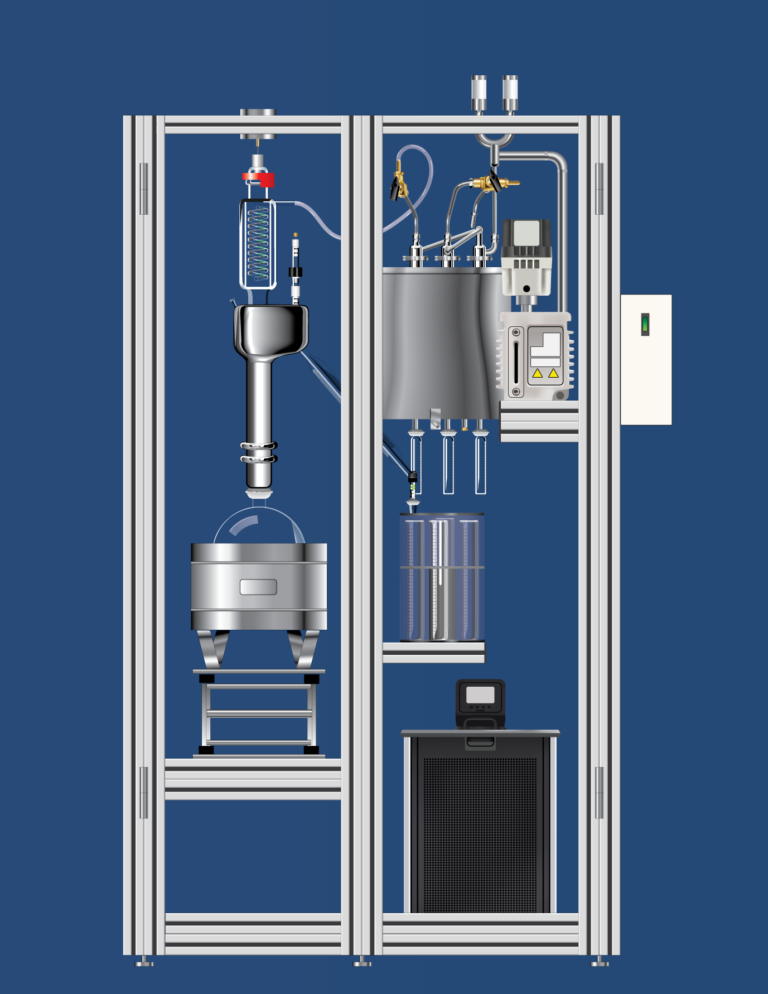

by PaulTired of chasing vacuum leaks, streaks and residual terpene smell in your THC distillate? Try spinning band distillation on your crude extract. No leaks Stop chasing vacuum leaks and using globs of messy vacuum grease (vacuum grease is not food grade). Spinning band distillation uses o-ring joints that are vacuum tight with every use. […]

Carbon scrubs and other filter media for cannabis oil extracts Carbon scrubs can be used to remove color from cannabis oil extract and THC distillate. Other materials are also used as filter media such as diatomaceous earth, fullers earth, bentonite, kaolinite and alumina silicate. While filter media may remove color from cannabinoids, it may also […]

Short Path Distillation – Just Getting Started Short path distillation is an entry level system for making THC distillate from crude extract. Its simplicity and low cost make it attractive to those new to making distillates. Making THC distillate with the short path is exciting at first but in time the excitement can turn to […]

Keep it clean. High quality THC distillate should be odorless. It doesn’t take much terpene to give a whole batch of an off smell. Proper cleaning of the distillation system between batches will get rid of any lingering terpenes after distillation. Clean the Distillation Column in Place With spinning band distillation, ethanol can be distilled […]

Distillation Rates Comparison

by brblogHow do different methods of distillation stack up against each other? System (Size) Distillation Rate Liters of Distillate Number of Passes Final Purity Total Time Short Path 1 (Average) 0.5 L/hr 10 L 2 90% 40 Hours Short Path 2 (Large) 1 L/hr 10 L 2 90% 20 Hours Wiped Film 1 (Average) 0.75 […]

True boiling point distillation distills crude oil from the initial boiling point up to 370-400 °C. D2892 is the ASTM test number. It is most commonly used to test crude oil and crude oil blends. It is sometimes used to distill condensate although that is outside the scope of D2892. The distillation typically takes place […]

Wiped Film and “The Split”

by brblogDid you know that during a decent first pass in a wiped film that 50% of your starting material can go to waste? The 50/50 split is the perfect example of the low-efficiency of a wiped film. If your crude extract is 50-70% cannabinoids, then how can 50% of the material be waste on the […]

Short Path Distillation Short path distillation is an introductory distillation technique sometimes used in labs in their start up phase. Short path produces usable but lower quality oil often in the 80% cannabinoid range after 2-3 passes. A common problem during short path operation are vacuum leaks which lead to degradation and dark oil. Spinning […]

Cannabis Oil Extraction – Crude Oil Extraction Consumption of cannabis has shifted over the years from smoking the plant to the use of concentrated cannabinoid oils. Vaping, dabbing, and edibles are becoming the most popular ways to use cannabis oil. These oils which are rich in THC and CBD are made by extracting the cannabinoids […]

Not all Crude Oil is the Same. How can you do Quality Control? Refineries buy large volumes of crude oil. But when a 500,000 barrel tanker arrives, how do they know they are getting what they paid for? How do they know that it hasn’t been mixed or “cut” with low value compounds to increase […]

Latest Blog Posts

Instant THC and CBD Potency in Edibles by Near Infrared (NIR)

by Paul on August 14, 2021

B/R Solvent Recyclers, Safe Recycling since 1986

by Paul on August 9, 2021

Touch Screen Makes Solvent Recycling Easier

by Paul on August 8, 2021

Measure THC, CBD and more in Real Time During CO2 Extraction with Near Infrared

by Paul on August 7, 2021

SCB-15 THC Remediation Case Study

by Paul on July 14, 2021

Questions?

Contact us for more information on our products and services.