Process For this THC remediation case study, we started with 40 kg of un-winterized, non-decarbed CO2 extract. We heated the material overnight using heat blankets to liquefy the extract for easy pouring. There was a significant amount of water mixed with this batch of extract. We raised the reactor lid and tilted the reactor forward […]

B/R’s THC Remediation SCB-15 has several advanced safety features to provide you with peace of mind. Reactor Lid Sensor Your operator will almost always remember to fasten the reactor lid closed before starting the remediation process. But what if they forgot? We’ve got you covered. The reactor lid has a sensor that detects when the […]

The software driving automated THC Remediation can make a huge difference in the safety, operation and traceability. Operating Parameters for your starting material The touch screen prompts the operator for starting material, weight, material type, and cannabinoid profile. This information is used to determine the optimum parameters for your starting material. The information also provides […]

Cold Trap During remediation, unwanted contaminants such as residual solvent, water, and terpenes are stripped from the oil and captured by the cold trap. The weight loss from the removal of these contaminants will depend on the number of contaminants in the starting material. About half the THC and some CBD also are captured by […]

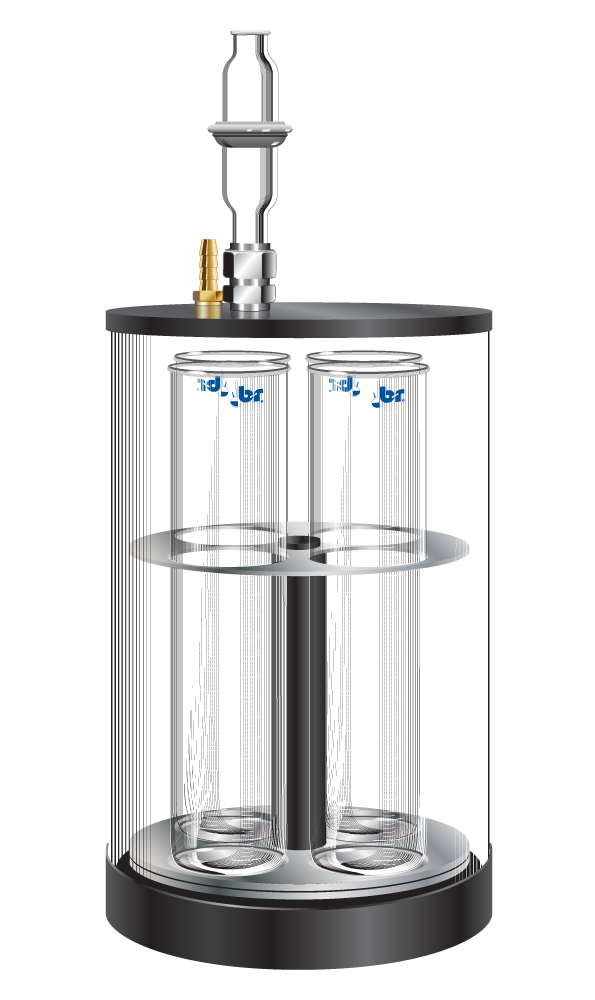

How to Load the SCB-15 THC Remediation Reactor Loading a THC Remediation system with 100 liters of oil can be a chore. The SCB-15 has some nice features to make the loading process as painless as possible. The THC Remediation system lid is a large, stainless steel piece of technology with lighted viewing window, stirrer […]

With the explosion in popularity of Delta-8 THC, many different methods of creating a legal D8 product came about. Nearly all SOPs in use employ an acid to convert CBD to Delta-8 THC. One thing all methods have in common is that Delta 9 THC is an intermediate product. This becomes one of the trickiest […]

Before you learn how to empty receivers of cannabinoids using a microwave, please be advised there are several ways this can go wrong. This blog post does not purport to address all the possible safety concerns. Please consult your safety officer for full professional guidance. High-purity THC/CBD distillate will be very viscous. If it is cold […]

Various types of crude cannabis extract can be successfully distilled into high purity cannabinoid distillate. With that in mind, it’s critical that the crude always be properly prepared prior to a vacuum distillation process. Depending on the type of extract being distilled, this can include one or more post-extraction steps, such as: Rough particulate […]

Carbon scrubs and other filter media for cannabis oil extracts Carbon scrubs can be used to remove color from cannabis oil extract and THC distillate. Other materials are also used as filter media such as diatomaceous earth, fullers earth, bentonite, kaolinite and alumina silicate. While filter media may remove color from cannabinoids, it may also […]

Spinning band distillation separates the cannabis oil extract according to the boiling points of the components. Mono-terpenes have the lowest boiling points, so they are collected first. They can be found in the cold trap receiver due to their low boiling points. Residual ethanol is collected next in the fraction collector followed by the higher […]

Latest Blog Posts

Instant THC and CBD Potency in Edibles by Near Infrared (NIR)

by Paul on August 14, 2021

B/R Solvent Recyclers, Safe Recycling since 1986

by Paul on August 9, 2021

Touch Screen Makes Solvent Recycling Easier

by Paul on August 8, 2021

Measure THC, CBD and more in Real Time During CO2 Extraction with Near Infrared

by Paul on August 7, 2021

SCB-15 THC Remediation Case Study

by Paul on July 14, 2021

Questions?

Contact us for more information on our products and services.