With the explosion in popularity of Delta-8 THC, many different methods of creating a legal D8 product came about. Nearly all SOPs in use employ an acid to convert CBD to Delta-8 THC.

One thing all methods have in common is that Delta 9 THC is an intermediate product. This becomes one of the trickiest parts of the process because any product containing greater than 0.3% by weight of THC is federally illegal in the US. Next is the issue that running your reaction for too long will cause the loss of the target cannabinoids.

Making a Compliant and Safe Product

Detection and monitoring of CBD, D8, and D9 levels gives the progress of the reaction. The end of an ideal reaction should have:

- Minimized the amount of D9 THC (less than 0.3%)

- Maximized the amount of D8 created

- Minimized the amount of side reactions and products

- Used as much of the CBD starting material as possible

If you were to monitor the reaction by HPLC then your results are delayed 30-50 minutes while the sample is run.

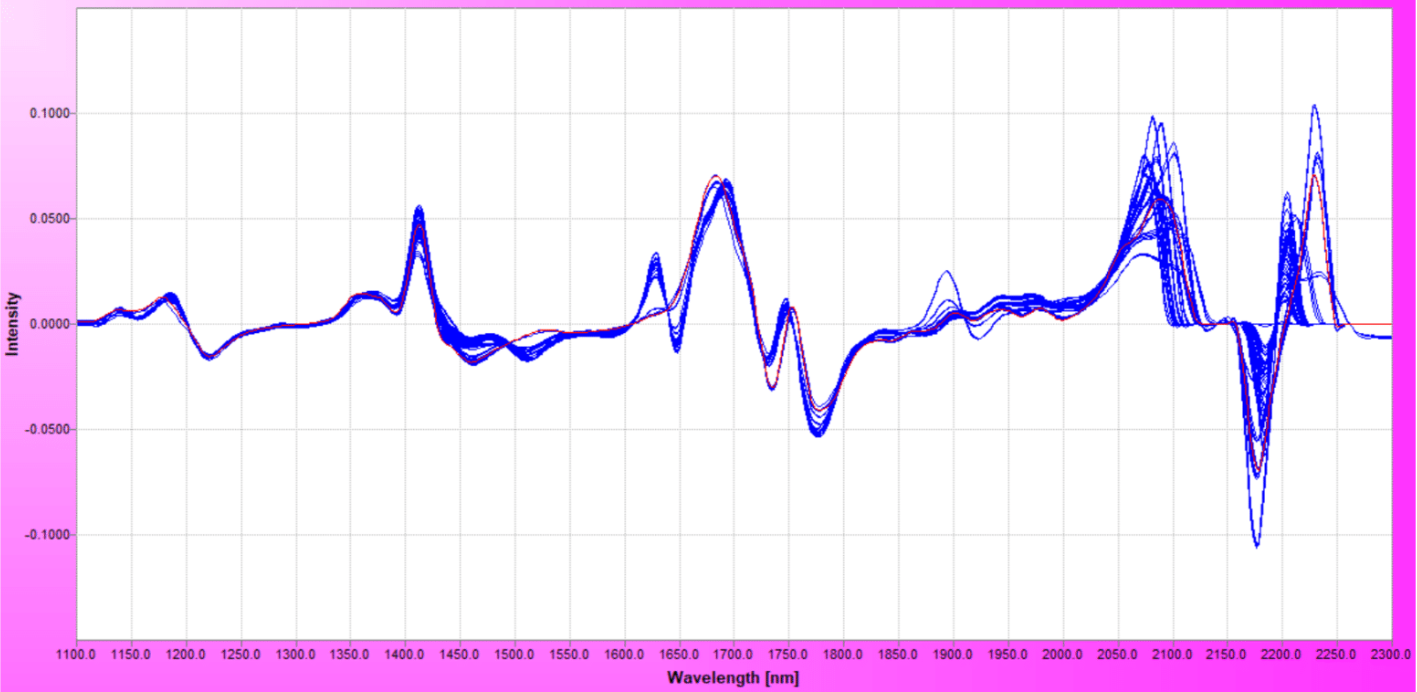

NIR gives instant and continuous feedback about your reaction and gives you the control to create the best product. NIR monitoring is capable of measuring Delta 9 THC, Delta 8 THC, CBD, and many other cannabinoids down to concentrations 0.1% of lower.

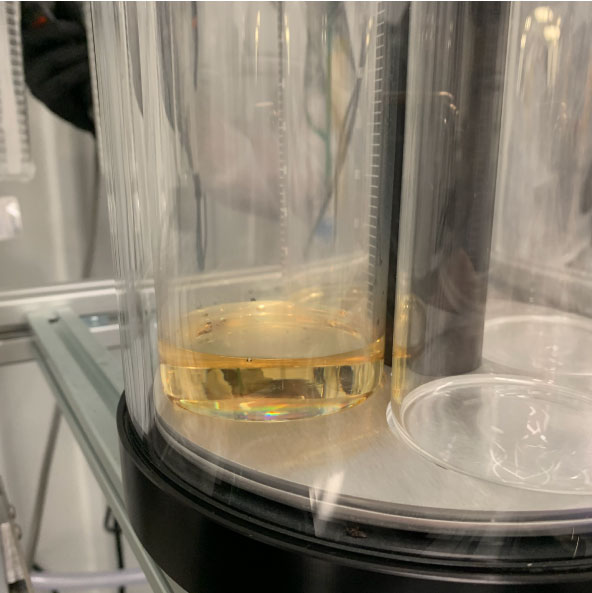

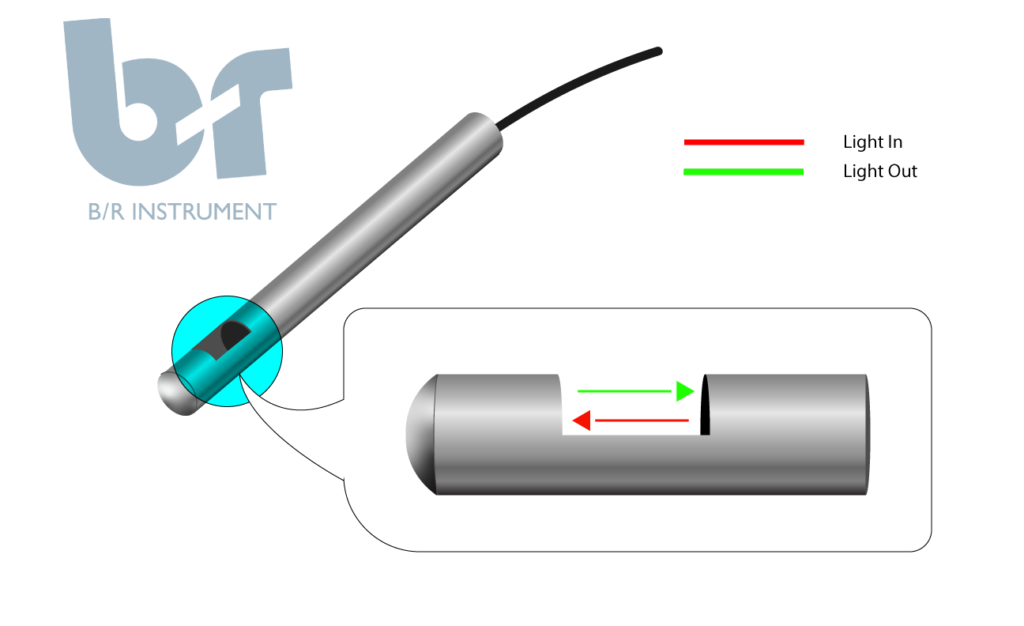

The NIR probe is mounted directly in the reaction chamber so that the reaction can be monitored in real time.

The absorption of NIR light by the sample is analyzed by chemometrics to determine the concentration of CBD, THC D9, THC D8 and other cannabinoids in real time. This is crucial information to maximizing THC D8 and minimizing THC D9 production.

Leave a Reply