Cold Trap

During remediation, unwanted contaminants such as residual solvent, water, and terpenes are stripped from the oil and captured by the cold trap.

The weight loss from the removal of these contaminants will depend on the number of contaminants in the starting material. About half the THC and some CBD also are captured by the cold trap.

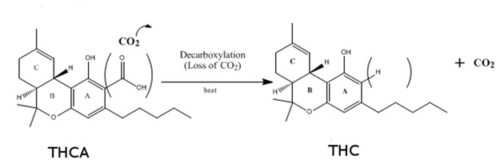

Decarbing

The remediation process uses heat. If you have not decarbed the starting material beforehand, the remediation heat will decarb it. The loss of CO2 will represent approximately a 13% loss of weight for the cannabinoids being decarbed.

Transfer Loss

Transfer loss is the largest source of loss during remediation. There are two transfers, getting the starting material into the reactor and getting the remediated material out of the reactor.

It is difficult to get all of the viscous sticky oil out of their buckets. However, if you heat the buckets with heating blankets overnight, the material will be less viscous and easier to transfer. Additionally, using squeegees and spatulas improves recovery but keep in mind there is always some starting material left behind.

Transfer of the remediated oil out of the reactor and into the final containers is aided by heating the reactor and the draining from the drain valve at the bottom of the reactor. However, some transfer loss is still unavoidable.

Leave a Reply