Is Solvent Recycling A Lot Of Work?

by brblogIf you have 5 minutes a day, you have enough time to recycle your solvents. That may sound like an exaggeration but recycling doesn’t take much time. A B/R recycler does most of the work for you. You just need to give it solvent to recycle, push the start button and….that’s it. The recycler does […]

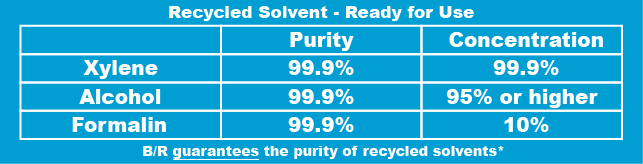

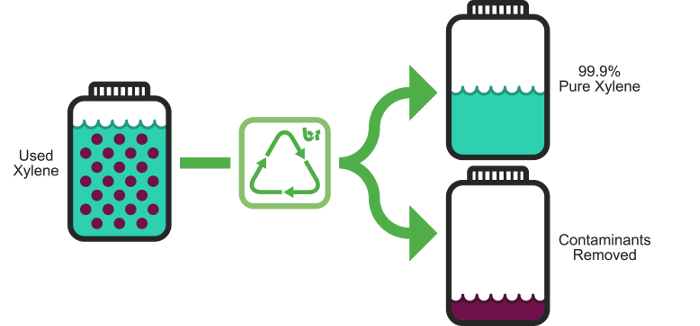

How Pure Are Recycled Solvents?

by brblogThe recycled purity can depend a lot on the recycler being used. With a B/R recycler you can expect high purity recycled solvents. The table below shows typical purity and concentrations. A manufacturer should be willing to guarantee the recycled product purity and concentration in writing. Not only should the purity be high but the […]

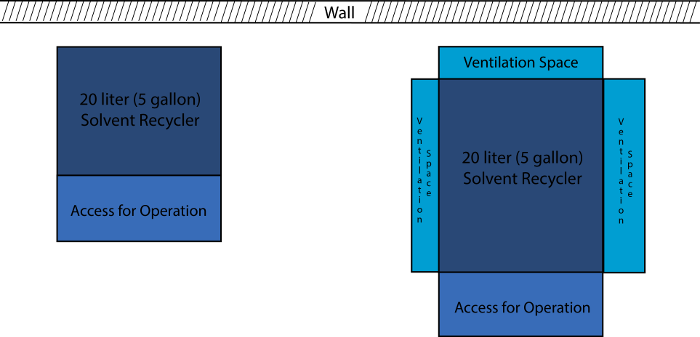

Q: Our lab is already crowded. Does a recycler take up much space? Space is always in short supply. Choose a “space efficient” recycler and you are on your way to saving. Every recycler has a set of written installation requirements. That gives details about what a suitable space is. These requirements are there to […]

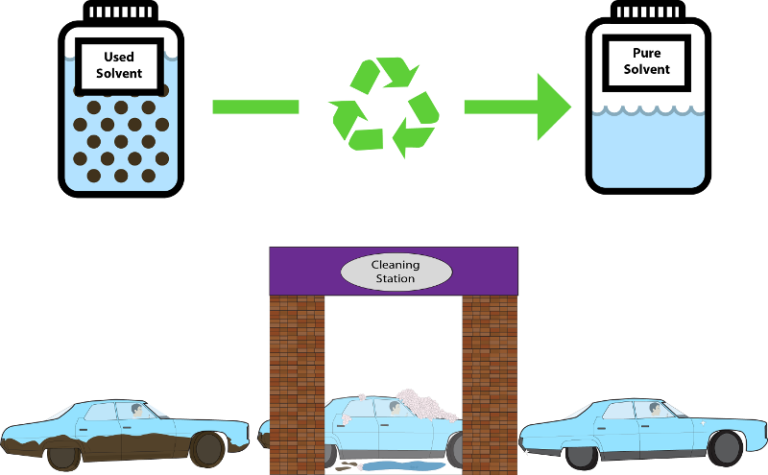

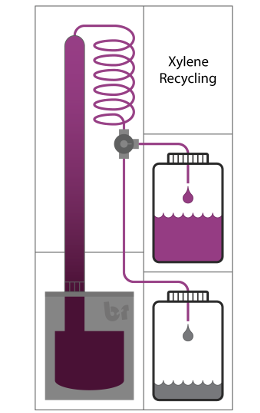

5 Reasons To Recycle Solvents

by brblogBy now you’ve heard that many histology labs are recycling their xylene, alcohol, and formalin. What are some reasons to recycle solvents? Don’t Throw Solvents Away – Recycle! You don’t throw your car away whenever it gets dirty – you clean it. The same is true for used solvents. They’re still perfectly usable – they […]

Q: My old recycler needed water and a drain. Do today’s recyclers need a water hook up? No, you don’t need a water hook up or drain. Older solvent recyclers worked great but used condensers cooled by water. Today’s solvent recyclers use condensers cooled by air. So no water or drain is required. Q: Does […]

How many times can I recycle a solvent?

by brblogA B/R recycler can recycle a solvent forever! Solvents used for tissue processing or staining becomes contaminated with stain, water, fat, protein, wax, and biological materials during use. The recycling process removes these contaminants from the good solvent. Reuse of the solvent is unlimited since it is brought back to the original purity each time […]

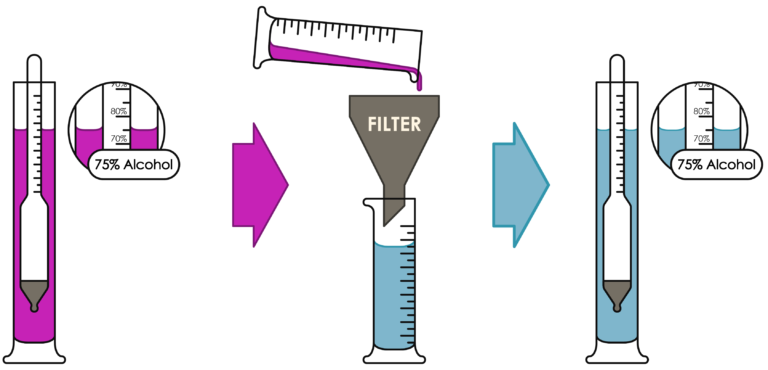

Do filter based solvent recyclers work?

by brblogDo filter-based recyclers work? The answer is both yes and no, but mostly no. There are commercial filter recyclers available for alcohol and formalin. However, there are no filter recyclers for xylene on the market. Alcohol – What does a filter recycler do? With use, the alcohol concentration gradually gets weaker. This is due to […]

Can I recycle xylene substitutes?

by brblogQ: Our lab wants to switch to xylene substitutes. Can they be recycled? Actually, xylene substitutes are easier to recycle than xylene. Their higher boiling points make it easier to separate from the contaminants. The primary reason for using a xylene substitute is that they have much lower toxicity than xylene. Unfortunately, they are much […]

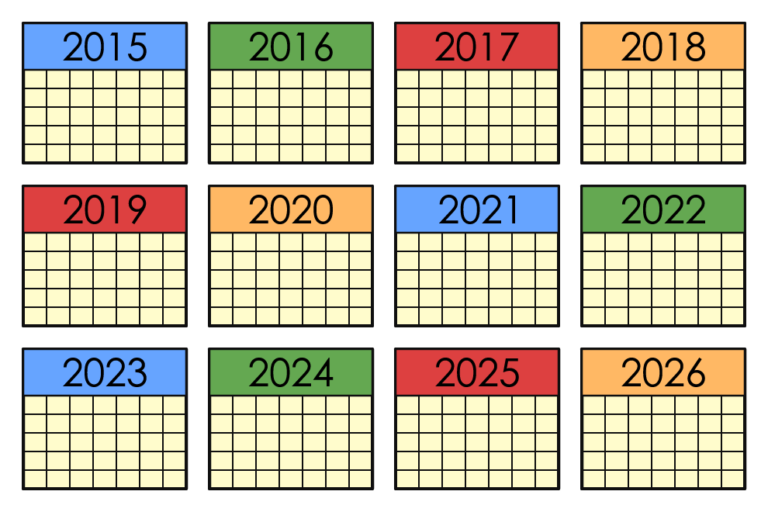

How long does a Solvent Recycler last?

by brblogQ: How many years will a solvent recycler last before it needs replacing? 10 to 15 years or…Longer. Do you remember your cell phone from 15 years ago? The lifespan of a recycler should be similar to the lifespan of the other equipment in you lab. Think about how long a tissue processer, stainer or […]

No, B/R recyclers do not require special ventilation or a special room. B/R Solvent recyclers are closed systems – no special ventilation needed. B/R solvent recyclers are closed systems. The distillation process is safely contained inside the all metal recycler. There is no place for the solvent to escape, so no additional ventilation needed. Q: […]

Latest Blog Posts

Instant THC and CBD Potency in Edibles by Near Infrared (NIR)

by Paul on August 14, 2021

B/R Solvent Recyclers, Safe Recycling since 1986

by Paul on August 9, 2021

Touch Screen Makes Solvent Recycling Easier

by Paul on August 8, 2021

Measure THC, CBD and more in Real Time During CO2 Extraction with Near Infrared

by Paul on August 7, 2021

SCB-15 THC Remediation Case Study

by Paul on July 14, 2021

Questions?

Contact us for more information on our products and services.