With a 20 liter (5 gallon) recycler you can easily recycler 5000 to 10000 liters (1300 to 2700 gallons) of solvent in a year. Typical operating costs to recycle 10000 liters of solvent would be about $200, or about $0.02 USD per liter ($0.07 USD per gallon).

It’s a great idea to understand all of the costs associated with recycling. The main costs are electrical power, operator time and consumables

Power

Most recyclers are connected to a standard power outlet (15 amps at 115 VAC or 10 amps at 200 VAC).

The average 20 liter (5 gallon) recycler will use approximately 3 Kwh per batch.

At an average cost of $0.12 USD per Kwh, recycling a batch of solvent would use $0.36 USD of electricity. Obviously, electricity isn’t a significant operating cost.

Operator Time (Manpower)

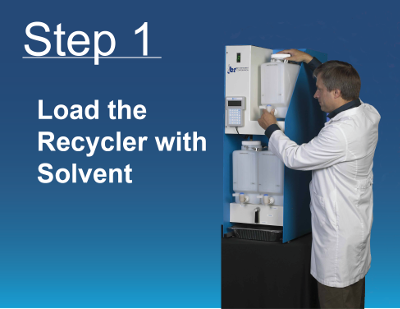

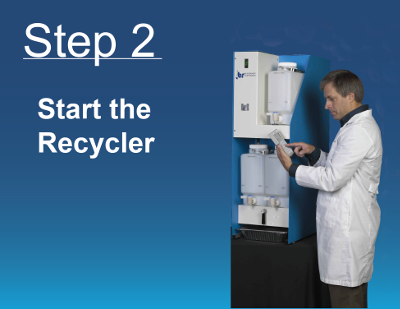

A typical recycling process requires about 5 minutes of operator time per batch. 3 main steps are preformed:

If one batch is recycled each day, that would be around 25 minutes per week of operator time.

Consumables

During the first year of use, a recycler shouldn’t need much in the way of consumables. After the first year of operation there might be a few gaskets and other inexpensive items that need replacing. The average cost per year for consumables for a B/R recycler is about $100 USD.

Leave a Reply