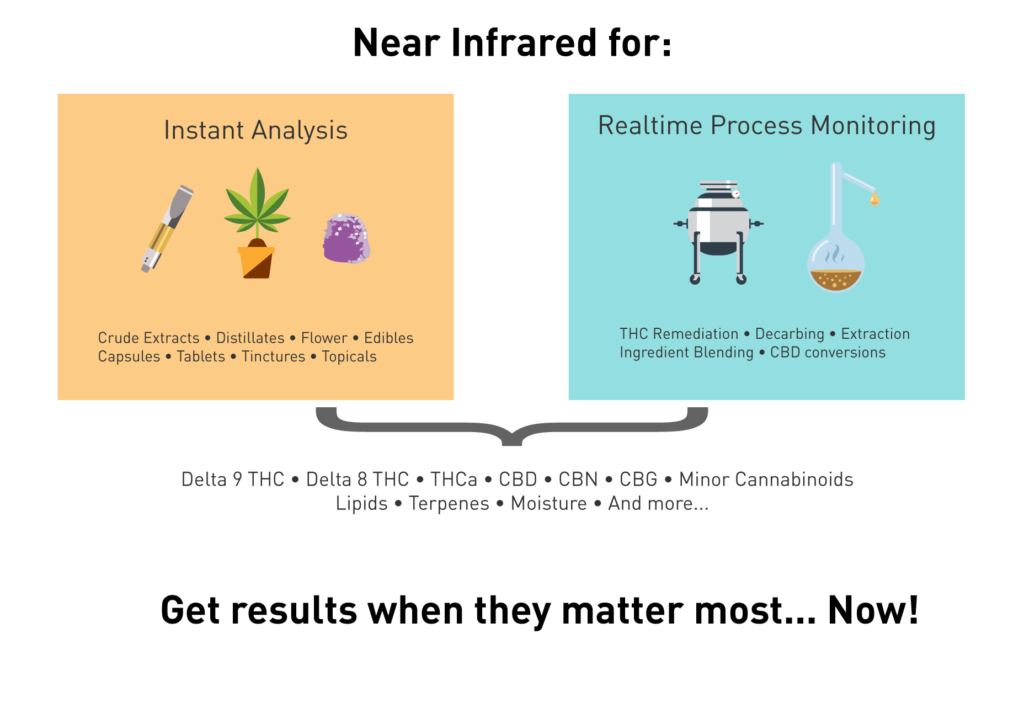

Instant Potency for THC and CBD Consumer Products

Instant analysis of crude extracts, distillates, flower, edibles, tablets and more by lab grade near infrared analysis. Near infrared (NIR) can produce accurate, repeatable analysis of cannabinoids, waxes/fats, terpenes, moister and more. It can differentiate THC Delta 8 from Delta 9. It can distinguish the acid form of cannabinoids from the decarbed form (i.e. THCa from THC or CBDa from CBD). It can measure minor cannabinoids as well.

Instant NIR analysis makes 100% potency testing of THC and CBD products possible. 100% potency testing is a powerful GMP tool that assures the each and every portion sold has the exact THC/CBD concentration promised.

Homogeneity of THC and CBD Consumer Products

Near Infrared has been used for decades for quality control in the pharmaceutical industry. NIR can detect potency in medicines. It is also well suited for detecting when formulations are fully mixed (homogenous). Knowing when homogeneity is achieved prevents overmixing or undermixing which can produce inconsistent potencies in the final product. NIR is an important link in the GMP chain, assuring consistent potency for customers.

Monitoring of Cannabinoid Processes in Real Time by NIR

Know what is happening in your process now so that you can act now! No 20-50 minute delay while waiting for HPLC results.

Collect data continuously throughout the process. Optimized Process = Optimized Profits.

GMP traceability for pharma quality products.

Some examples are below.

Real Time Monitoring of THC Remediation by Near Infrared

Monitor THC levels (and other cannabinoids) in real time with NIR. Know exactly when the desired THC level is reached to avoid over processing. Don't waste time and unnecessary CBD losses.

Real Time Monitoring of Decarboxylation of THCa, CBDa or CBGa by Near Infrared

Decarbing THCa, CBDa or CBGa isn't difficult but it isn't easy to know when decarboxylation is complete. Real time monitoring of the important cannabinoids helps determine when decarbing is finished to avoid over cooking the extract. Real time monitoring also allows tracking of CBN creation so that oxidation can be minimized.

Real Time Monitoring of the Conversion of CBD to Delta 8 THC by Near Infrared

Delta 8 THC (D8) is a popular psychoactive product at the moment since it is not a federally regulated substance. There are several ways to convert CBD to D8. It is very helpful to monitor the conversion in real time using NIR. The point where CBD is fully converted to D8 is easily identified by NIR so that the process can be stopped to avoid unwanted side reactions.

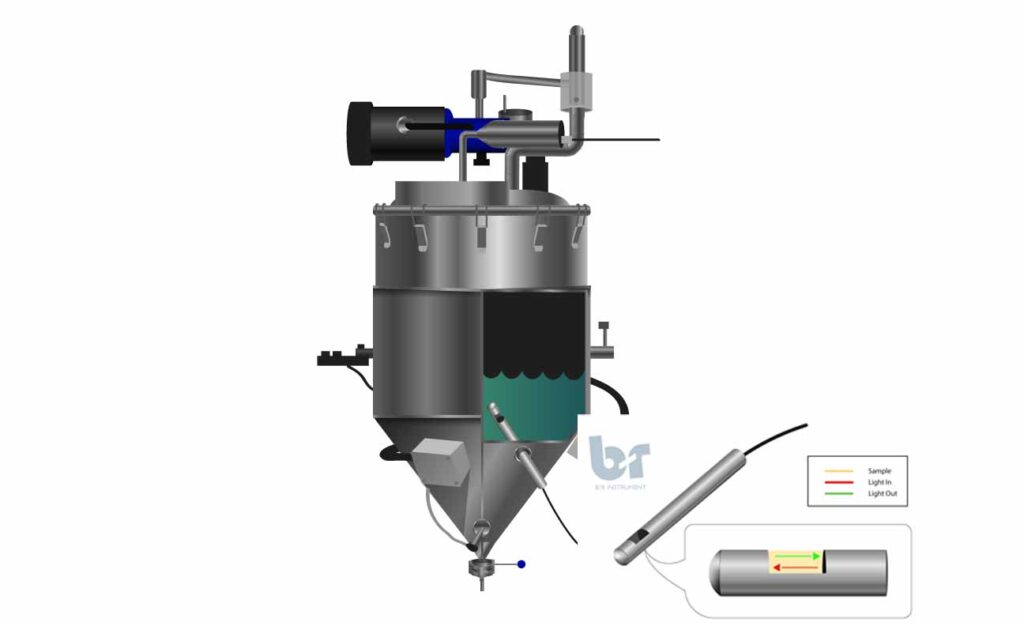

Monitor Extraction of THC and CBD from Cannabis and Hemp in Real Time with NIR

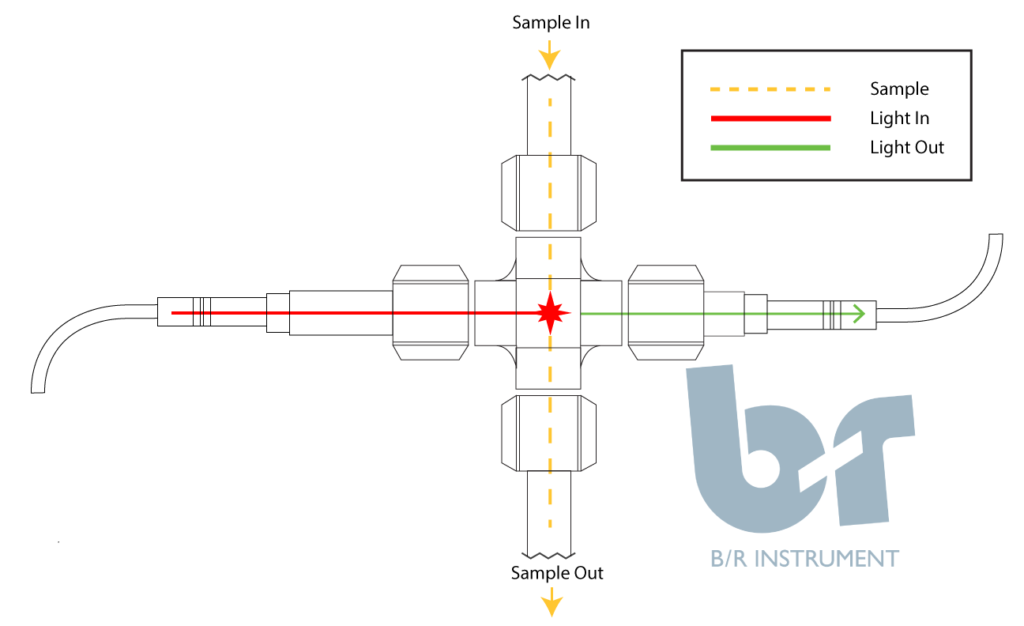

Monitoring the extraction of THC and CBD from flower, trim and biomass in real time is very powerful. Whether it is finding the perfect temperatures and and pressures for CO2 extraction or the optimum mix for hydrocarbon extraction or the ideal temperature and time for ethanol extraction, near infrared is the tool for the job. Continuous real time measurements provide a road map of how the extraction is proceeding. See when the THC and CBD are extracting and when they form a "long tail". See when fats/waxes, terpenes and other non-cannabinoids start coming out. NIR flow cells are easily installed in the extractor.

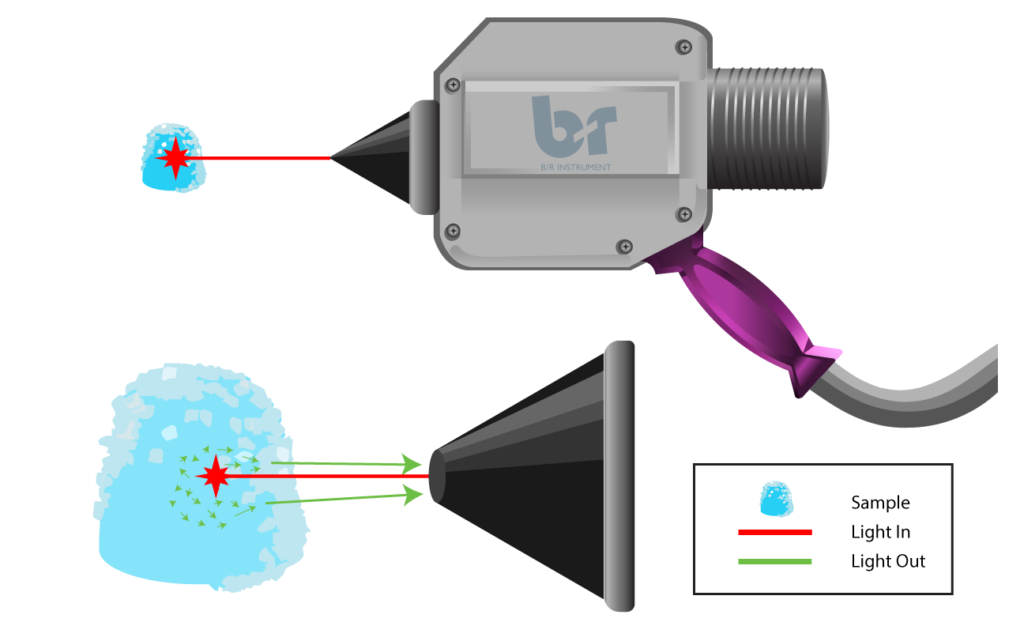

How Near Infrared Works

Near infrared is a form of spectroscopy. Near infrared wavelengths are "beamed" into a sample. Various chemical bonds such as O-H, C-H, N-H absorb specific wavelengths of NIR light. The amount of absorption is proportional to the concentration of the substance of interest. Chemometrics uses a series of samples that have know concentrations of the substances of interest. These are used to calibrate or "teach" the NIR system about the materials of interest.

The B/R NIR uses an internal standard to correct for drift. It is immune to ambient light and vibration. This achieved using AOTF technology. The resulting stability and repeatability are unmatched in the industry. NIR has be used for decades in the pharma, agra and chemical industries. It has also been used to detect water on the moon.