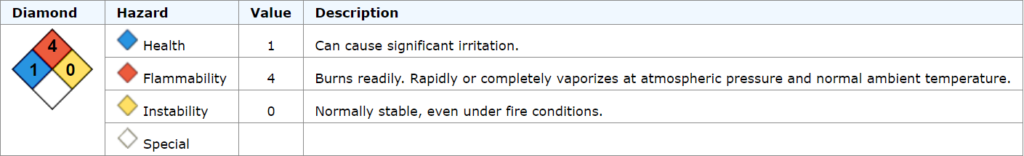

Disclaimer – this post does not address all the safety issues for the crystallization of CBD, Pentane, and other volatiles. They can be very dangerous due to their low flash points. Don’t try this without consulting your safety officer and evaluating all of the possible safety concerns. As always, wear safety glasses and other personal protective gear when working in a lab.

Credit https://cameochemicals.noaa.gov/chemical/1288

Quality CBD crystals begin with Quality CBD distillate

The starting material should be extracted from CBD oil that has been winterized and distilled. The CBD distillate should be clear. Any cloudiness means there are contaminants like water, waxes, and fats. If the oil is cloudy, try winterizing again until the oil becomes clear.

If you crystallize oil with contamination, it will lead to poor yields.

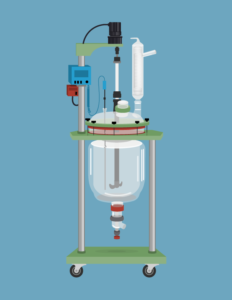

CBD Crystallization Equipment

Use a jacketed vessel with stirring to dissolve and crystallize the CBD. A heating/cooling bath is connected to the vessel jacket. Use this to control the temperature of the vessel.

The ACS-grade pentane will be the solvent. This can be dangerous stuff, so make sure to consult your safety officer!

Dissolving CBD Oil

Next, dissolve the clear CBD oil in pentane. Make sure the jacketed vessel’s vent/condenser is connected to an appropriate blower motor or fume hood for pentane vapors. The boiling point of pentane is 36 °C. Even at lower temperatures, pentane will release many vapors.

BE CAREFUL AND TAKE ALL PROPER PRECAUTIONS! Make sure the vessel condenser is cooled to -20 °C. Add 1 part pentane to 2 parts CBD oil (some oils require slightly more or less pentane) in the jacketed vessel. Turn on stirring and turn on the heating bath and set to 45 °C. Wait until the solution reaches 45 °C and all the oil has dissolved.

Precipitation

Set the bath to 5 °C, and slow the stirring. As the solution cools it will become more viscous. Then, adjust the stirrer to keep the RPM above 120.

CBD crystals will spontaneously form or “crash out” of the pentane solution. Keep reducing the temperature to at least -10 C. What temperatures you use and how they change over time can change the growth of the crystals.

Collect CBD Crystals

Once precipitation stops, flush or physically remove The CBD crystals from the reactor. Vacuum filter the crystal/liquid slurry to remove the mother liquor from the CBD crystals. Rinse the crystals with ice-cold pentane to rinse impurities from the crystal surfaces. More rinses with pentane can improve poor color, but losses in total yield will occur. Keeping the CBD and materials cold during this step will help give you a better yield.

Reprocess Mother Liquor

The mother liquor still will contain dissolved CBD. However, you can reprocess this solution! One caveat is that the mother liquor will accumulate THC over time. This sets a practical limitation to the number of crystallization.

CBD Purity

CBD distillate with 70 – 75% CBD content can be crystallized to produce CBD isolate (crystals) with a 90+% purity or higher.

Conversely, CBD distillate with less than 70% CBD can be crystallized to produce CBD isolate with 85+% purity or higher.

You can re-dissolve CDB crystals and then recrystallize them to improve their potency even further.

May 8, 2019 at 3:39 pm

I have been making my isolate with 70 + percent distillate. Could you make isolate with a lower percentage? Say like 50%?

May 17, 2019 at 4:44 pm

Hi,

Yes it is possible to crystallize CBD from low purity crude or poorly refined oil. However, low starting purity will reduce both yield and purity of the crystallized CBD. The lower purity CBD “isolate” will have more color, smell, and THC content than if you used distillate. This will cause you to need a recrystallization step which is not the end of the world but has a real cost.

Luke

January 7, 2020 at 3:13 am

What is the loss to iso from diss?

January 9, 2020 at 11:17 am

Hi,

See my previous comment for the math. The isolation yields between 60-80% of the CBD.

Luke

April 17, 2020 at 10:49 am

Hi,

with this method and a high refined oil can i precipitate cbda? or form two phases future separation?

more solvent more time and more cold?

thanks

April 20, 2020 at 8:36 pm

Hi,

CBDA crystallization is more difficult than this process. The most success I have seen is when people crystallize it like they would THCA. Hydrocarbons and adsorbents used together seem to help.

May 19, 2019 at 1:19 pm

I am interested in doing this process not on a lab, but more industrial process, do you know of someone who sells this equipment? Regards

May 20, 2019 at 12:44 pm

At this time, there is not an industrial scale solution on the market. Anything like that would be custom designed and manufactured.

October 12, 2019 at 12:22 am

What is the system capacity?

Yield and throughout of CBD isolate?

October 13, 2019 at 3:23 pm

Hi,

We are able to prove vessels with 20 L up to 100 L capacity. Yields may vary from about 60-80% depending on your parameters and input purity. 20 kg of distillate in our 50 L could be turned to about 12 kg of isolate in approx 6-8 hrs.

February 25, 2021 at 3:39 pm

Hi Luke,

If you are using a 100L reactor, what is the maximum amount of distillate you can isolate. Based on your above numbers with a 50L it sounds like a 100L would allow you to do 40KG of distillate with ~20Litres of Pentane and would it be the same type of timing of 6-8 hrs to produce what I assume is double the amount of isolate (24KG).

February 26, 2021 at 5:57 pm

No there is an issue with your math.

The density of pentane at room temp is 0.626 g/mL. 40kg of of distillate into 20 litres of pentane is nearly a 4:1 ratio of distillate to pentane. I don’t recommend that kind of saturation for your first crystallization.

You really need to only use weights rather than volumes. Volume is temperature dependent so the conditions of your lab or how you run your process can really change the values.

2 parts distillate to 1 part pentane (by weight) is probably an ok starting point. For a 2:1 ratio you are correct though. 40 kg of distillate is about the max. 40kg of distillate to 20kg pentane (32ish liters of pentane) = 70 some liters total.

I don’t like to go above the lid in whatever reactor, and some reactors “total” volume includes that headspace. The headspace for a 100 liter reactor is probably 10 liters depending on shape, etc, etc.

Time is going to be dependent on a lot, but yeah if your heaters and chillers can keep up then 8 hours is pretty reasonable.

-Luke

August 15, 2019 at 12:16 pm

Alex,

We can help you with with your CBD crystallisation if still of interest?

https://www.nitechsolutions.co.uk/

You can contact me at george.butcher@nitechsolutions.co.uk

George

October 31, 2019 at 1:13 pm

Check out bvv or across international for a filter reactor. It’s a one stop shop piece of equipment that makes making isolate much easier

May 28, 2019 at 1:29 pm

My CBD isolate smells like pentane when it comes out of the tank we use for crystalization. However when it is distillate I have that same smell is it the the terpenes causing it? The ratio used is 2:1 pentane being 2 and left for 20 hours in the tank at -10 Degrees C.

May 28, 2019 at 4:34 pm

Hi,

The isolate will contain solvent molecules trapped within and on the surface of the crystals.

To remove residual solvent (pentane):

1) Wash the raw crystals with cold (probably around -40 C) pentane on a vacuum filter

2) Crush/Grind the crystals finely

3) Use a vacuum oven to gently purge more solvent

4) Flip the crystals in the vacuum oven to expose any trapped surfaces and continue the purge until tests indicate no pentane.

-Luke

June 12, 2020 at 3:59 pm

good point

June 11, 2019 at 12:03 pm

What (inexpensive but effective) testing equipment would you suggest we buy to test the pentane levels and CBD content of our isolate?

June 11, 2019 at 3:09 pm

Hi,

You are probably best having two different pieces of equipment for pentane and CBD. The reason being the types of detectors that can be used to quantify those compounds are different. For example CBD gives a UV spectrum where pentane does not. Also, due to the underlying principles of the two methods, their separations will occur differently.

For detecting residual pentane levels, Gas Chromatography system with a basic detector should be relatively inexpensive. The most workable cheap option would be an FID (flame ionization detector). Slightly more expensive would be a quadrupole mass spectrometer. The quadrupole mass spec is a great detector for GC because compounds are fully separated and identified. Liquid Chromatography is better for quantifying CBD. This can be paired with a DAD (diode array detector, a form of UV-Vis spec.) or a mass spec too.

Luke

August 23, 2019 at 4:28 pm

Hi Luke, great info, thank you so much!

I was curious about how you remove the pentane used to wash the crystals. In a comment above you recommend leaving the crystals in the reactor until tests show no pentane. GC-MS testing takes time. Are you recommending leaving your batch in place until testing is done?

August 24, 2019 at 1:13 pm

Hi Tom,

Once the majority of the pentane has been removed by vacuum filtering, it should be perfectly safe to transfer. You will need to transfer the crystals to a vacuum oven to remove residual levels that will show up on GC-MS. The isolate would probably not get purged correctly if left to dry in place.

We need to use a vacuum oven because in a regular oven the CBD would somewhat obviously melt! The vacuum helps reduce the boiling point of everything and anything. This way, less heat and time are needed to fully purge.

June 13, 2019 at 2:10 pm

Two questions. Firstly, why is pentane used instead of hexane ? Secondly, is it possible to grow a seed crystal for larger structures using the process described above ? Thanks for the well written instructions!

June 14, 2019 at 12:47 pm

Hello,

A big reason is due to the lower boiling point of pentane. The increased volatility makes handling and safety a little trickier, but with the benefit of easier removal from the final product. Since hexane and heptane require basically the same level of equipment precautions it isn’t a big deal to work with pentane.

Other reasons may come down to availability, price, and what solvents are permitted in a state or particular lab. Also, I have heard anecdotally that hexane has a lower residual ppm limit than pentane in some areas. However I am not familiar with all laws so take that with a grain of salt.

If you want to grow large single crystals you will need a modified process. Some steps would include much slower temperature changes, fewer seeds crystals/nucleation points, and a less saturated solution.

-Luke

July 8, 2019 at 10:57 pm

When you use pentane to crystallize your distillate is it somehow attracted to the CBD molecule specifically?

Or is the process simply reducing all cannabinoids in the same ratios and pulling out the remaining liquids?

July 10, 2019 at 1:14 am

Pentane is chosen because at warm temperatures it can dissolve the full spectrum of cannabinoids. When cooled however, CBD becomes very insoluble and crashes out. THC and the tons of the other cannabinoids stay in the pentane creating a pretty pure crystal of CBD. Impurities in/on the crystals would be small amounts of things like cannabinoids, terpenes, and solvent.

November 12, 2019 at 1:43 pm

Have you had any issues with retained pentane captured within the crystal structure?

November 12, 2019 at 10:38 pm

Hello,

Sometimes in larger crystal formations it can be difficult to remove residual levels. Small, powder-like isolate is easy to dry of solvent between filtering and a vacuum oven.

If you have large crystals, you may need to mill them somehow.

Luke

July 9, 2019 at 2:00 pm

Luke,

We are trying to determine how many vacuum ovens we will need to process our CBD isolate. When our lab is operational, or when your distillation equipment arrives ; ) , we will be able to produce approximately 600 kilos of Isolate per month. Based on that figure how many vacuum ovens would you recommend? Lets use the Across International 1.9 CF oven as a starting point.

I really appreciate all your input!

Ross

September 19, 2019 at 7:30 pm

Hey folks,

I’m looking to explore how much mass loss is typically experienced when processing distillate in to Iso.

Considering the 70-75% distillate becoming +90% isolate example used, with a 75% distillate starter ending with a 90% isolate is the mass loss at all related to the change in CBD % (a 15% loss in mass from start to finish)?

What observation in mass change have you experienced from start to finish?

Any co-relations you base expected yield outcomes on?

Thanks!

September 20, 2019 at 8:55 am

Hi,

For distillate to isolate yields, the range is normally between 60-80% dependent on many factors. So if you have 1000 g of 80% CBD Distillate, you can expect between 480 and 640 grams of isolate. I have not heard of yields getting much better than 80%. It is very easy to get worse yields though!

1) 1000 mg * 0.8 = 800 mg of potential CBD.

2) 800 mg * 0.6 = 480 mg

3) 800 mg * 0.8 = 640 mg

After the initial crystallization, you must generally “wash” your crystals with cold solvent. This takes away a lot of impurities, but does take some CBD away as well. After this point the losses are mostly based on transfer from container to container.

October 28, 2020 at 6:04 pm

What are just a couple of the main things that might have influence on the yieldage or crystallization rate I seen in one comment you may be mentioned the shape or the size of the vessel that it’s in having a influence could you elaborate thanks

October 17, 2019 at 10:35 am

Hi Luke,

I am having issue with the pentane which is trapped inside the crystals.

Would you let me know please at which temperature, crystals would be dried in the vacuum oven for residual pentane? which vacuum oven will you recommend ?

October 17, 2019 at 12:11 pm

Hello,

You want to use minimal heat to prevent melting the crystals. Maybe start with 30-40 C. Deeper vacuum will definitely help too.

You may need to grind the crystals to a finer consistency as well. Grinding the pentane laden crystals is dangerous if there is a spark. Also, flipping/agitating the CBD crystals in the tray should help ensure particles on the bottom do not trap pentane.

I do not have any brand I recommend. Cheaper options should work fine, but may require modifications like different gaskets to hold vacuum or better cold traps.

Hope that helps,

Luke

November 22, 2019 at 4:25 pm

If you have pentane trapped inside the molecular structure of the crystal, you have taken youir temperature down to fast, forcing the crystal to grow, but encapsulating the pentane. You must melt the isolate back to a liquid and re-crystallize with approx a 10:1 iso to solvent ration, taking your temperature down much slower. You’ll find that the re-crystallization can happen in the upper 30s (degrees C) when doing this.

January 16, 2020 at 2:21 pm

I need a 400 liter vessel machine.

February 11, 2020 at 3:07 pm

[…] the end, CBD is isolated as a crystallized powder that manufacturers may add to anything. People may add CBD Isolate to food, drinks, and even vaping […]

February 25, 2020 at 7:39 am

How much hemp plant is needed to produce 20kg of distillate to produce 12kg of isolate

How much does the equipment here cost? Please contact me

February 25, 2020 at 11:00 am

Probably in the ballpark of 200 kilos. You can expect about a 5-10% yield from biomass to distillate.

February 25, 2020 at 2:56 pm

Nice article Luke! Appreciated the info, the simplicity and the answers to all of these questions here.

March 6, 2020 at 3:19 am

Hey great explanation i do it similar way at my lab , my question is what remains in crystals exepect the cbd?

March 11, 2020 at 10:37 pm

THC and other cannabinoids will always be present to some degree. Perfect crystals don’t exist so it just depends how hard you want to look.

I see CBDv pretty often!

April 12, 2020 at 8:50 am

Asking How can i make CBD infused water, i really want to start something.

Cooldrinks.

April 13, 2020 at 1:16 pm

Hi,

There is a lot of trial and error. Otherwise you will need to get a consultation or purchase a recipe.

First, you will need to find a surfactant to bind to your CBD. There are many blends and combinations of surfactants used in the food and beverage industry. If you look at this list of common ones, you may recognize some of them from a lot of ingredient labels.

Second, you will need to taste and try. A lot of them add bad tastes or make chalky drinks. It also changes the shelf life of something like even just water.

A useful tool is an ultrasonic blender. Might want to look at a spray dryer too.

One restriction is that your percent weight of CBD is relatively low. I believe depending on the surfactant that only around 20% of your powder is CBD.

-Luke

June 3, 2020 at 4:34 pm

Hello,

I started distillate of 76% for my crystallization and I ended up getting 91%of CBD. How can I improve its purity to 98%?

June 11, 2020 at 4:36 pm

Dissolving the crystals and recrystallizing might be the easiest way. Make sure to wash your isolate on the filter with cold solvent when collecting. This helps remove many impurities on the surface.

-Luke

July 24, 2020 at 12:10 am

Hello, I have a simple and maybe silly question regarding the crystallization, Is this process done under vacuum or just at atmospheric pressure? my lab is well above sea level and I was just curios if pressure played a role in this process. Thank you for all the knowledge.

July 24, 2020 at 1:05 pm

This process is normally done at or really close to atmosphere.

Vacuum or even positive pressure can be used to change crystallization in certain scenarios. This is most of the time due to changing the evaporation rate of the solvent.

Vacuum will make the solvent evaporate or even boil, which can cause crystals to be “shocked” out of the solution.

Pressure will slow the rates of evaporation, which in turn will give slow crystal growth. Pressurizing flammable solvents is dangerous though. An example of this method is the “diamond miners” or mason jars growing large and pure THCA crystals.

-Luke

January 31, 2022 at 4:46 pm

Hi Luke, Very informative article,

We’re thinking about doing an iso run with a nitrogen atmosphere under a very light vacuum. Question is what is happening if the crystals are “shocked” out of the solution and whether or not that is desirable for higher/cleaner yields?

-Charlie

February 1, 2022 at 1:01 pm

A rapid crash will result in tons of small crystals that will result in a powder when dried.

I prefer the rapid crash for many reasons.

1) Easier to handle. The slurry can be drained/pumped/poured over a filter to be washed. No need to break up large chunks of crystals.

2) Efficiency. Your time goes from hours or days to literal minutes.

3) Little difference in purity. I have made plenty of 99%+ CBD isolate fast crashing. In theory, slow growth will be more pure, but as long as THC is less than 0.3% it probably doesn’t matter very much.

-Luke

July 19, 2021 at 9:06 pm

Is it possible to do this without a condenser? Or will Pentane vapors not allow for Crystals to form?

July 20, 2021 at 5:56 pm

The condenser is necessary to prevent solvent (often pentane) from escaping the reactor and entering the room where it becomes an explosion and fire hazard. Doing crystallization without a condenser is extremely dangerous. Other critical safety precautions are not mentioned here. You should consult with your safety officer before attempting crystallization.

August 21, 2021 at 8:07 pm

Hello I would like to know if I can use heptane as I have seen reports of a person that heptane instead of pentane and the crystallization did not happen in the same way as pentane the procedure was to warm the temperature 5 C degrees below the boiling temperature and cool down to 0C degrees slowly.

August 27, 2021 at 1:34 pm

Yes, many people use heptane. The procedure is a little different but it still follows the same pattern.

1) Add heat to completely dissolve input oil in your solvent of choice

2) Cool the solution of solvent and oil to precipitate crystals.

-Luke