The cannabinoid decarboxylation step is performed differently in nearly every lab. To create certain products, THCa, CBDa, CBGa, and many other cannabinoids must all get decarbed.

Why and how does Decarb happen?

One example is that CO2 extractors often decarb the biomass to improve their efficiency and yield. A second is when some manufacturers prefer to decarb in a sealed reactor to minimize oxidation.

Cannabinoids naturally decarboxylate very slowly over time. This reaction happens much faster at the elevated temperatures for solvent recovery, so some just run the rotovap or FFE a little longer and call it good enough. Distillation is also a guaranteed way to fully decarb any material.

The point is, there are a ton of ways to solve this problem. One thing they have in common is that there is no standard way to check your progress. Decarb for too long, and you will oxidize or degrade your valuable cannabinoids like THC into CBN or worse yet, unknowns. Decarb for too short of a duration and lose optimization of your process.

How can you monitor the progress?

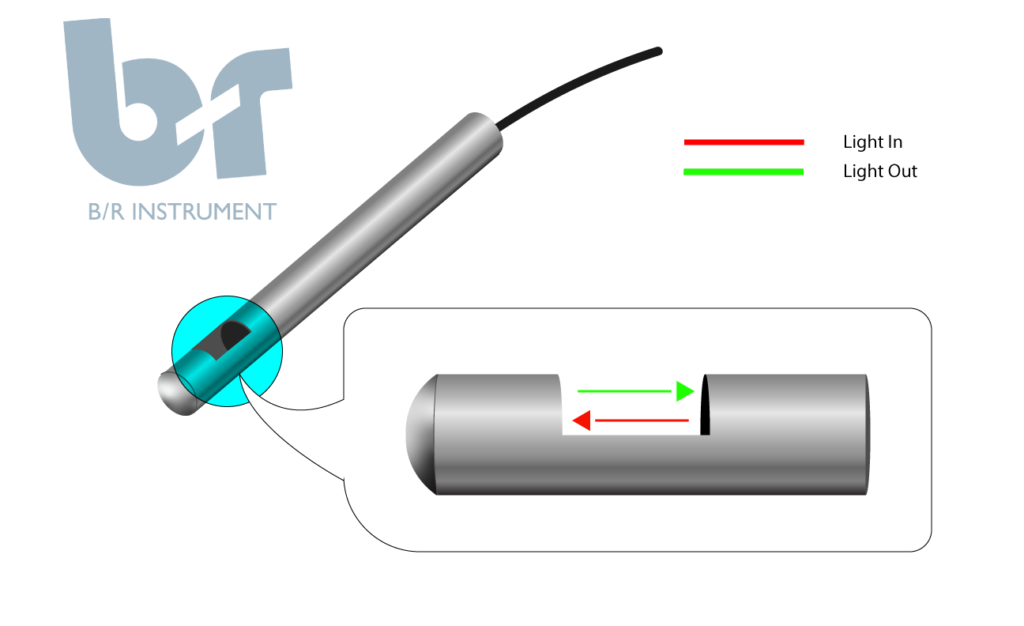

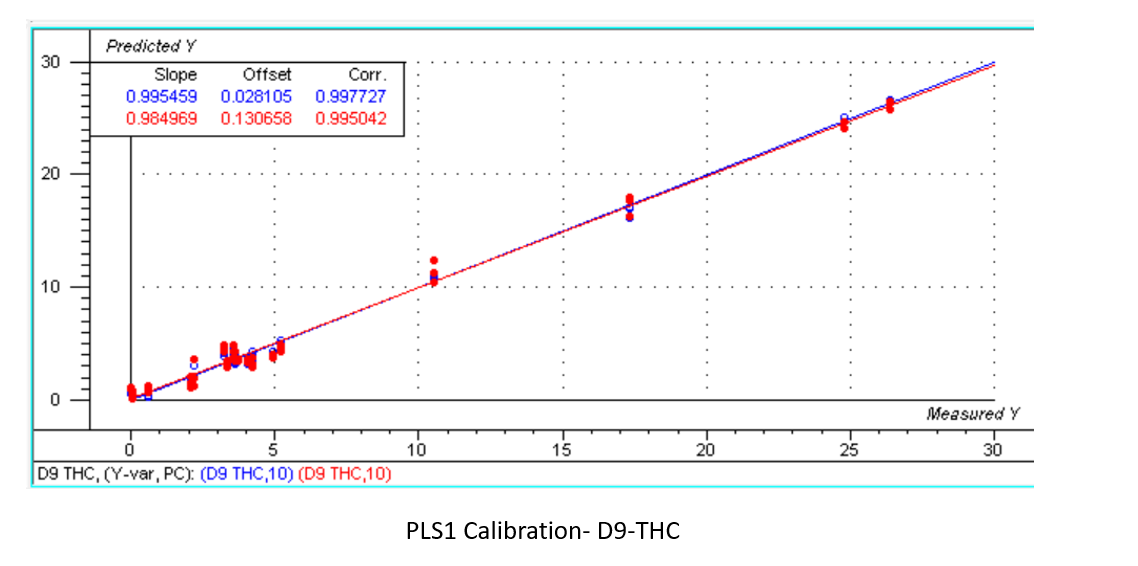

Using NIR detection, monitoring the decarboxylation of cannabinoids is simple. The carboxylic acid group responds strongly to some Near IR frequencies. This means that the loss of this group is easy to see using NIR! The reactor monitors the cannabinoids in real time, scanning the full spectrum of wavelengths up to 30 times per second. Most amazingly, no sample prep is required.

The alternative is to run an HPLC or GC which can take about 30-40 minutes per sample. Sample preparation takes a lot of your time and is arduous with many steps that need to be highly precise. This also introduces a level of human error in the data. Finally, it is also important to note that you cannot test for cannabinoid acids directly on a GC.

Leave a Reply