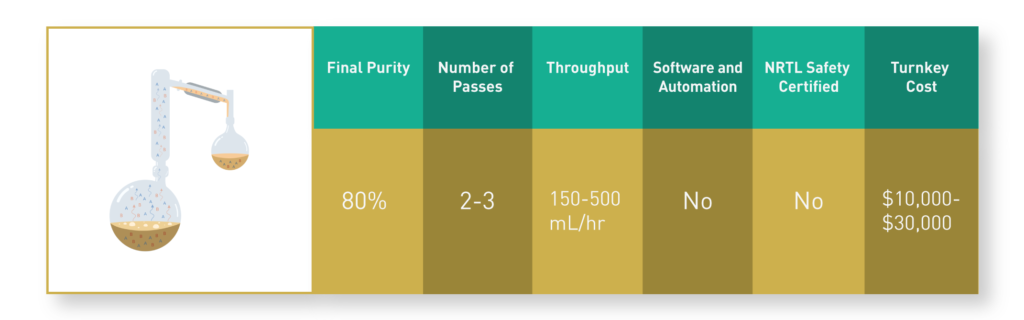

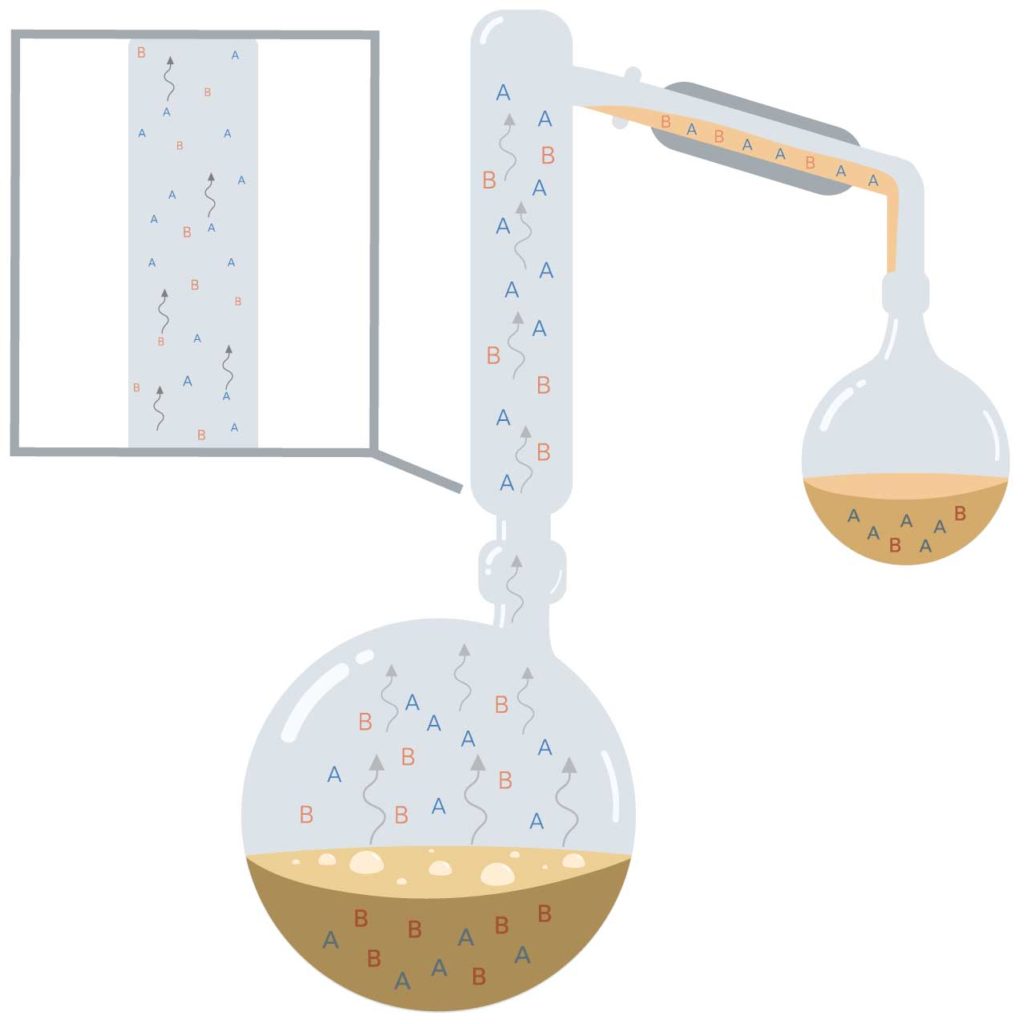

Short Path Distillation

Short path distillation is an introductory distillation technique sometimes used in labs in their start up phase. Short path produces usable but lower quality oil often in the 80% cannabinoid range after 2-3 passes.

A common problem during short path operation are vacuum leaks which lead to degradation and dark oil. Spinning band solves this problem by using vacuum tight o-ring joints that give a perfect vacuum seal with no vacuum grease.

As start up labs mature, they often migrate to spinning band distillation systems with higher throughput, higher purity, and more automation.

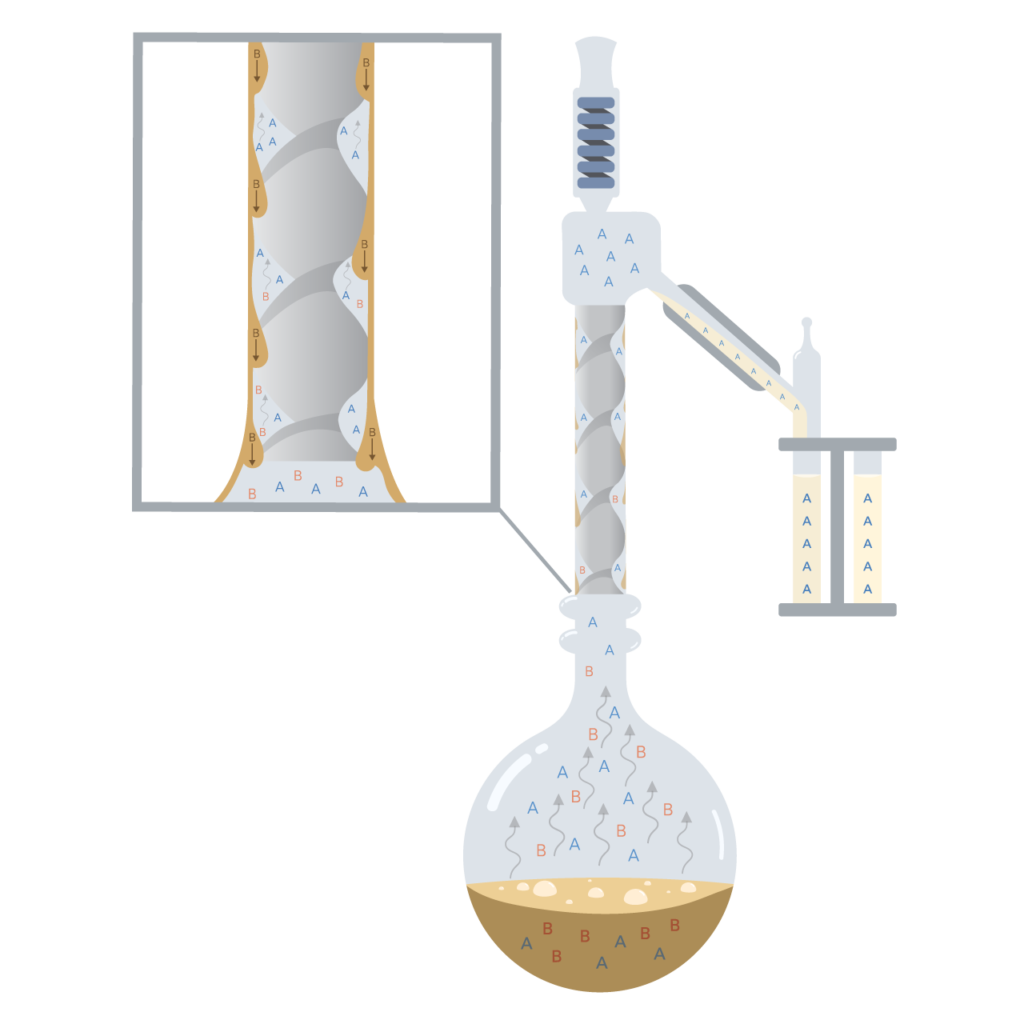

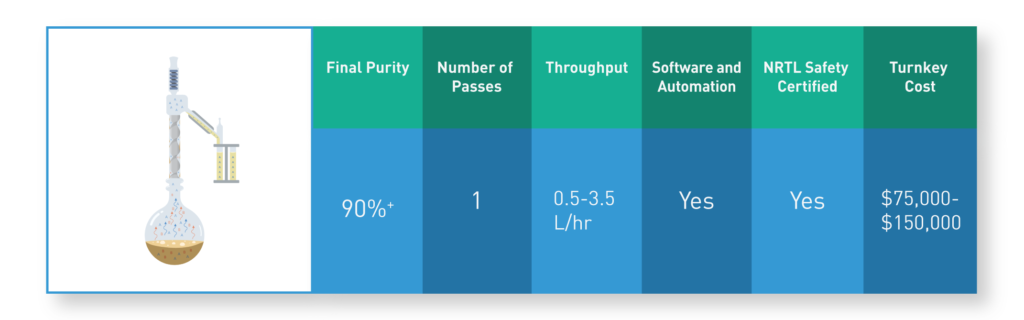

Spinning Band Distillation

Spinning band distillation offers a high-efficiency distillation column that can produce 90+% cannabinoid distillate in a single pass. A single-pass distillation means you’ll spend a lot less time distilling.

The spinning band acts as “dynamic” packing. Condensed oils are pumped back down the column while pure vapors rise unimpeded. The result is the highest purity oil in the shortest possible time.

Operation is streamlined by the high efficiency column in combination with our distillation software. B/R’s integrated software allows for automatic control of the distillation system. Variables like vacuum level, heat rate, bath temperature, and more are programmed and controlled automatically. Distillation results are also logged and graphed. Have a successful distillation? Replicate it!

With a few optional items you can even run the system remotely. Ask us how!

February 5, 2021 at 6:04 am

Hello :),

what kind of temperatures, vacuum and spinning band rotation speed would you prefer for spinning band distillation to get a high purity from delta9THC or CBD out of cruide cannabis extract?

Would you evacuate the spinning band system with nitrogen or argon, before distillate the cruide cannabis extract to prevent degradation from delta 9 THC to CBN or delta 8 THC?

Thank you in advance for your answer