Ethanol for easy and complete cannabis oil transfer

Extracted oil is viscous and sticky. It requires heating in order to transfer it and valuable residue left behind in the original container.

Extracted oil is viscous and sticky. It requires heating in order to transfer it and valuable residue left behind in the original container.

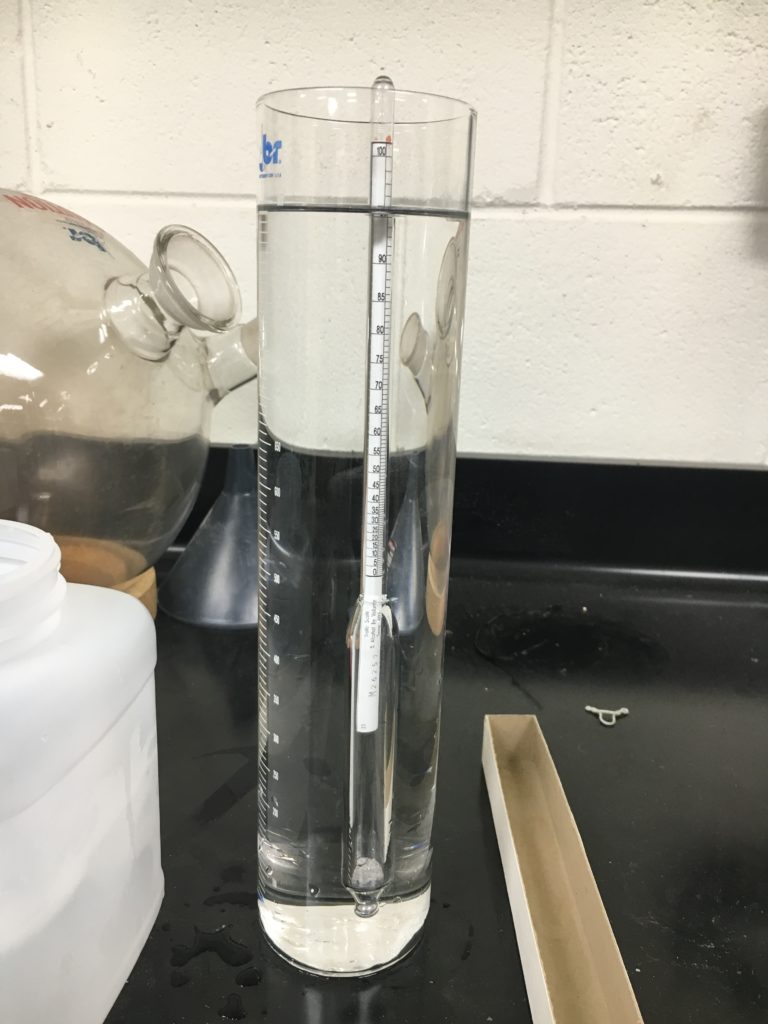

If you have ever run a rotovap, you will know the last bit of solvent always takes the longest to remove. The oil gets much more viscous as solvent nears depletion and traps solvent.

Having the extract in equal parts ethanol makes it much easier to transfer the oil. It pours easily at room temperature and residue is virtually zero. No valuable oil is left behind.

Spinning band distillation is very flexible and can handle feeds containing any amount of ethanol. Ethanol will be recovered during the distillation process and is separated from the terpenes and other contaminants.

For feeds from ethanol extraction where the ratio of ethanol to oil may be 10:1, you may want to strip ethanol in a rotovap/falling film evaporator down to something closer to 1:1 first in order to save time.

Does spinning band feed oil require dilution with ethanol?

In a word, no.

There is no problem distilling straight cannabis oil (no ethanol) in the spinning band distillation system. It distills just fine.

No spattering problems with spinning band distillation

Oil for wiped film distillation must be free of any traces of ethanol or other volitiles. Even small amounts of these in a wiped film system will cause spattering. Spattering will carry raw oil into the product receiver ruining the distillation.

Spinning band distillation can tolerate any amount of ethanol or other volitiles in the cannabis oil. These are removed automatically during the distillation and collected in the receivers.

Recycle Ethanol

Save money and recycle your ethanol. Ethanol is simple to recycle. It can even be recycled with the same spinning band distillation system used to distill THC/CBD. Most of the recovered ethanol will be 95% pure!

September 2, 2020 at 6:29 am

Hello was just wondering what operating conditions (pressure and temperature) this process operates at?

September 8, 2020 at 11:51 am

Hello,

Ethanol extraction can take place at any temperature really, but for best results, -80 C is desired. This will almost always be at atmospheric unless stated otherwise.

Ethanol removal takes place normally at 70-100 C. To get the residual amounts of ethanol out, you may need to apply vacuum or increase the temperature. The pressures used at this stage are typically light vacuum.

-Luke