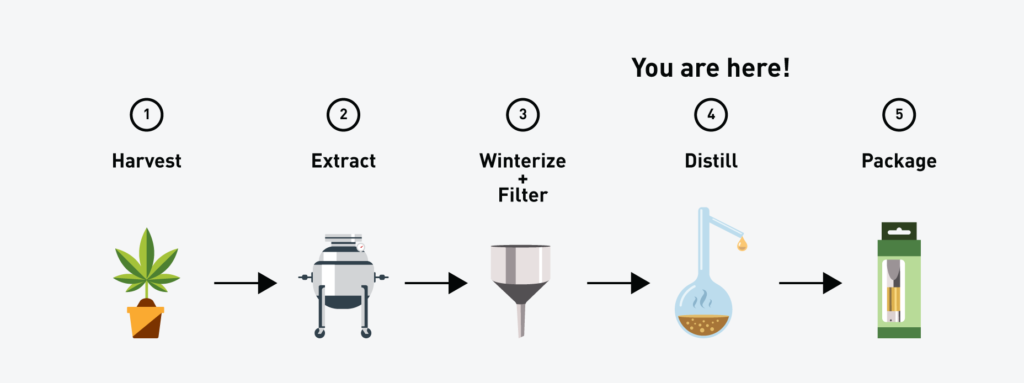

Ever wonder how THC/CBD products such as vape cartridges, dabs, and edibles are created? Read on to learn more about the cannabis oil products timeline!

1. Grow It

It all starts with “the grow”. Most cannabis grows are done in a controlled room. Light, water, temperature and other environmental factors are carefully regulated to maximize cannabinoid production. Cannabis plant genetics are also selected to produce the desired cannabinoid profile and concentration. Harvesting is timed with the peak cannabinoid production. The primary product is the “bud” or flower which contains the most cannabinoids and terpenes. Leaves are trimmed from the bud. These trimmings contain less cannabinoids than the bud. After harvest and trimming, the bud and trim are allowed to dry.

2. Extract It

The next step is to extract the cannabinoids. The three main types of extraction are hydrocarbon, ethanol, and CO2. The extraction process produces crude extract containing terpenes, cannabinoids, and fats/waxes. If the solvent was a hydrocarbon, the crude extract normally needs to be purged to remove the residual solvent. If the solvent was ethanol, it is convenient to immediately move into the winterization step.

3. Winterize It

Winterization is the cold filtering of crude extract to remove the fats and waxes. Fats and waxes cause “off” flavors and add viscosity. Typically a product will be dissolved in ethanol and then winterized several times, each time using a progressively smaller pore-size filter. Filtering also removes residual plant material from the extraction step.

4. Distill It

The winterized oil is then distilled to remove terpenes, volatiles, and residual oils. The three main types of distillation are spinning band distillation, short path and wiped film. Spinning band is a fractional distillation capable of producing high purity THC/CBD distillate in a single pass. Short path is an “introductory” methods that can make acceptable distillate but requires at least 2 passes. Wiped film can also make acceptable distillate in 2 to 3 passes.

5. Package It

When it comes to edibles, the distillate must be free of terpenes. Nobody wants their THC brownie to smell or taste like weed!

If the distillate is transparent and light in color, it is a good candidate for vape cartridges or dabbing. Add a few percent of high-quality terpenes back into the oil and fill your cartridges.

Learn More

Want to know more about how THC/CBD products are created? Contact B/R today!

March 11, 2019 at 12:08 pm

Hi, I need to know about viscosity of cannabis oil for edible product. please let me know if you have any information about that. I can find specific viscosity for the other oil at room temperature but not specific for cannabis.

Thanks,

Mahshid

April 5, 2019 at 12:36 pm

I am sorry, I do not know of anywhere to obtain that information. The viscosity changes greatly based on concentration and composition. High purity (~90% cannabinoids) are typically completely solid at room temperature. Around 80% purity, the oils can be poured without heating, but are still thicker than honey or syrup.

November 22, 2019 at 4:25 pm

I’m new to this. What about a decarboxylation step in your process flow chart above?

November 25, 2019 at 11:58 am

Hi,

You are correct. Decarb will happen at some point in this process. I also failed to mention solvent recovery, which occurs partly during distillation, but mostly before.

Decarb can happen in our distillation equipment. If using another distillation method, you can decarb before in a reactor. I don’t recommend using a hotplate or some open heating source because heating can be uneven and there is a lot of exposure to the air.

Decarbing as a separate step can be useful because it saves some time in the distillation process (~30ish minutes) and it can strip some of the very light and volatile terpenes that chew up your vacuum pump or hurt your vacuum level.

-Luke