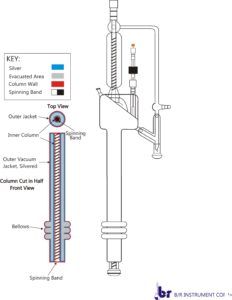

Those “things” near bottom of the spinning band distillation column are called bellows. They function as a flexible expansion joint. Glass is normally anything but flexible and these bellows are engineered to allow the expansion and contraction over the length of the column.

Distillations start at room temperature and goes up to the distillation temperature when boiling starts. The inner glass wall of the distillation column lengthens due to the rise in temperature. The bellows allow the outer wall of the distillation column to lengthen along with the inner column. Without the bellows the distillation column would be under stress during distillations and prone to breaking.

The longer the distillation column the more bellows are needed.

February 5, 2021 at 6:04 am

Hello :),

what kind of temperatures, vacuum and spinning band rotation speed would you prefer for spinning band distillation to get a high purity from delta9THC or CBD out of cruide cannabis extract?

Would you evacuate the spinning band system with nitrogen or argon, before distillate the cruide cannabis extract to prevent degradation from delta 9 THC to CBN or delta 8 THC?

Thank you in advance for your answer