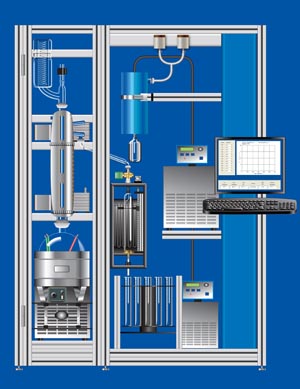

This distillation system is designed for the distillation of crude oil and petroleum products. Crude oil distillation can be complex and time consuming. Our crude oil distillation system includes everything needed to perform the ASTM methods, D2892 and D5236, for distilling crude oil. The system’s automation minimizes the operator time needed to perform the test. The equipment design makes the test straightforward and easier to perform.

Distillation Column Configuration

The crude oil distillation system can come in a wide variety of configurations with single or multiple distillation columns.

The packed column configuration is used to distill the crude oil up to a maximum 450°C atmospheric equivalent vapor temperature. It is sometimes called true boiling point distillation or D2892. The distillation column has 15 theoretical plates and complies fully with ASTM D2892. Pot sizes of 2 to 100 liters are available.

A variety of column packing types are available including Propak, Helipak, and structured packing. Other packing types are also available.

The vacuum pot still configuration is typically used to distill the residual material from the D2892 distillation out to atmospheric equivalent vapor temperatures up to 565°C or higher. The vacuum pot still complies fully with ASTM D5236. Pot sizes of 1 to 22 liters are available.

A two crude oil distillation column configuration is also available. Usually, one distillation column is the D2892 packed column (true boiling point) and the other is the D5236 vacuum pot still column. Only one distillation column is operated at any time. Both distillation columns share the same controller, fraction collector, vacuum control system, and recirculating bath.

Spinning band distillation columns are available in addition to traditional packed columns and vacuum pot stills. The spinning band distillation columns can accommodate pot sizes from 10 ml to 12 liters.

Automation and Accessories

All our crude oil distillation equipment is available in automatic or manually operated models. Manually operated crude oil distillation systems are inexpensive and simple to operate. Automatic crude oil distillation models are microprocessor controlled. The distillation functions are automated to make the crude oil distillation process easy and efficient from beginning to end.

PC Control

PC control minimizes the amount of operator time required for each crude oil distillation. Call up your stored program and let the PC perform the crude oil distillation. Each fraction has programmable open and close temperature cut points, heat rates, and reflux ratio. There is a programmable shut down at the end of the distillation run. The PC allows easy editing of each of the parameters while the crude oil distillation is in progress.

Fraction Collection

The fraction collector can automatically collect crude oil fractions based on temperature cut points at atmospheric pressure or under vacuum. Receivers come in a variety of sizes and are graduated for easy observation of the cut volume by the operator. The fraction collector comes in 4 or 8 place options.

Vacuum System

Distillation of crude oil above 200 °C must be performed at reduced pressures. The vacuum system includes a 2-stage mechanical vacuum pump, cold trap, pressure sensor and proportional control valve. The operator can input a vacuum set point from 100 mmHg to 0.1 mmHg and the vacuum system will automatically control vacuum to the set point level.

Recirculating Bath

The recirculating bath controls the condenser temperature in the range of -20°C to 100°C. The operator inputs the desired temperature and the bath automatically controls the temperature to that set point.

Spare Parts

A spare parts kit is available which includes the parts necessary to keep your crude oil distillation system operating. B/R Instrument stocks all parts for fast deliveries.

Specifications for D2892 Packed Columns (True Boiling Point)

- Distillation Column Efficiency: 15 Theoretical Plates

- Vacuum Range: 100 to 2 mmHg

- Packing Types: Propak, Helipak, Structured Packing (other packing available on request)

- Pot Sizes: 2 to 100 liters

Specifications for D5236 Vacuum Pot Still

- Vacuum Range: 100 to 0. 1 mmHg

- Pot Sizes: 2 to 22 liters