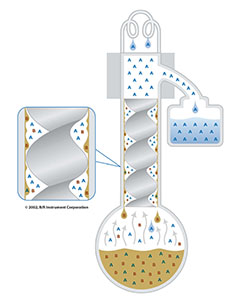

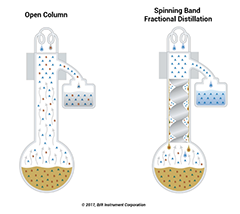

How does Spinning Band Work?

All distillations attempt to seperate a lower boiling point material (A) from a higher boiling point material (B). Spinning band distillation creates intimate contact between the vapors and the condensate in a dynamic process. It uses a helix rotating at high speeds inside the distillation column. The rotating “band” forces vapors into contact with a very thin layer of condensate that is refreshed thousands of times per minute.

What are the Advantages?

Low Hold Up

Less than 2 ml of material remains in the distillation column at the end of the run. Valuable material is not lost and cleaning is minimized.

Low Pressure Drop

The spinning band has very high “free space” and as a result has very low pressure drop over the length of the column. This is ideal for distilling sensitive or high boiling compounds.

High Efficiency

The spinning band offers the highest efficiency (most theoretical plates) for a given distillation column height meaning spinning band gives the highest purity possible.

What is the Throughput?

Our standard column has a throughput of 1 Liter/hour. Slower speeds can help reduce color, but have no impact on the purity of the final product.

What Sizes are Available?

Our standard sizes include 1,2,3,5,12, and 22 liters. All flask sizes are compatible with any standard distillation column, giving you flexibility when performing your run.