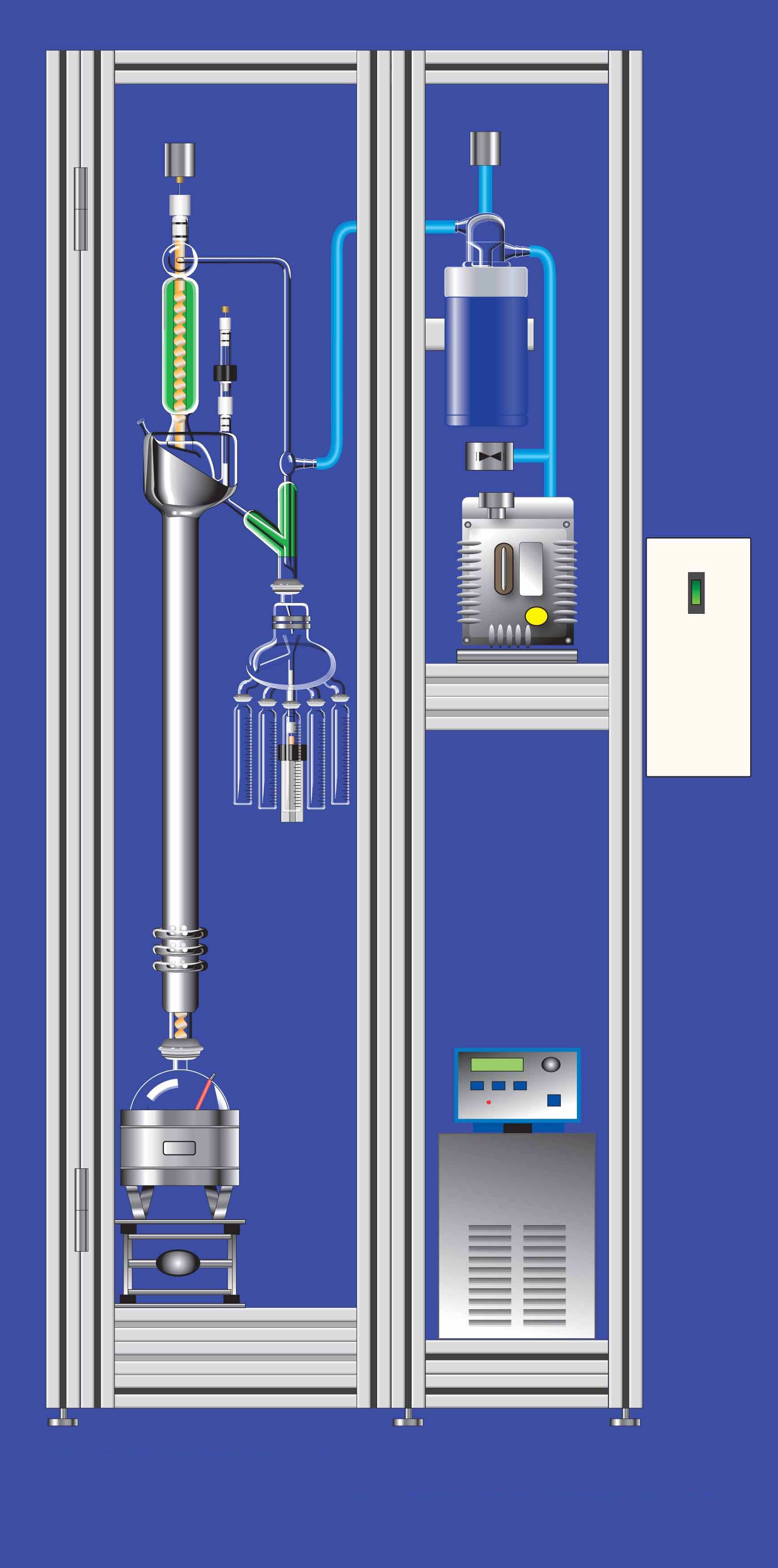

Spinning band distillation is a technique that uses a rotating helical band to create a high number of theoretical plates. The spinning bands can be made of Teflon or metal. Teflon spinning bands are used for distillations below 225 °C. Metal bands are used for higher temperature distillations where Teflon would become soft.

All distillations attempt to separate a lower boiling material (A) from a higher boiling material (B). Spinning band distillation uses a spinning band to force the rising vapors into close contact with the descending condensate. This intimate contact between the two phases produces a very good separation of the components.

The high number of theoretical plates makes spinning band distillation ideal for distillations requiring very good separation of components. Applications such as distillation of essential oils, crude oil and solvent recycling often use spinning band distillation to get the high purity fractions required.

The “low hold up” (material left behind in the distillation column after the distillation) feature of the spinning band distillation column makes it a popular choice for distilling high value materials such as essential oils, flavors and fragrances. The minimum amount of the high value material is left behind in the distillation column after the distillation is complete.

The high free space of the this distillation column allows distillations to be performed at lower temperatures, avoiding the application of excessive heat to the material.