Decarbing Cannabis Oil: THCA to THC

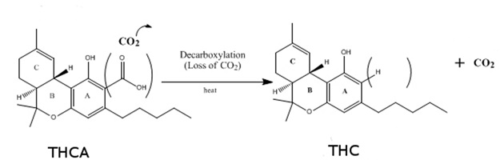

by brblogDecarboxylation, AKA Decarbing, is the process of spontaneously converting THCA to THC with heat (approximately 80-120 C). During decarbing THCA is converted to THC when the carboxylic acid group on THCA is removed liberating a CO2 molecule and leaving THC behind. Decarbing is important because THCA is not psychoactive, but THC is. Other cannabinoids like […]

Why Winterize? Proper winterization is an important step in creating a high purity extract. Winterization is the removal of lipids from crude extract. Lipids are fatty acids that are also extracted from the plant. It is typically the next step after extraction. Why winterize to remove lipids? Fats dilute the cannabinoid fraction, lowering the purity […]

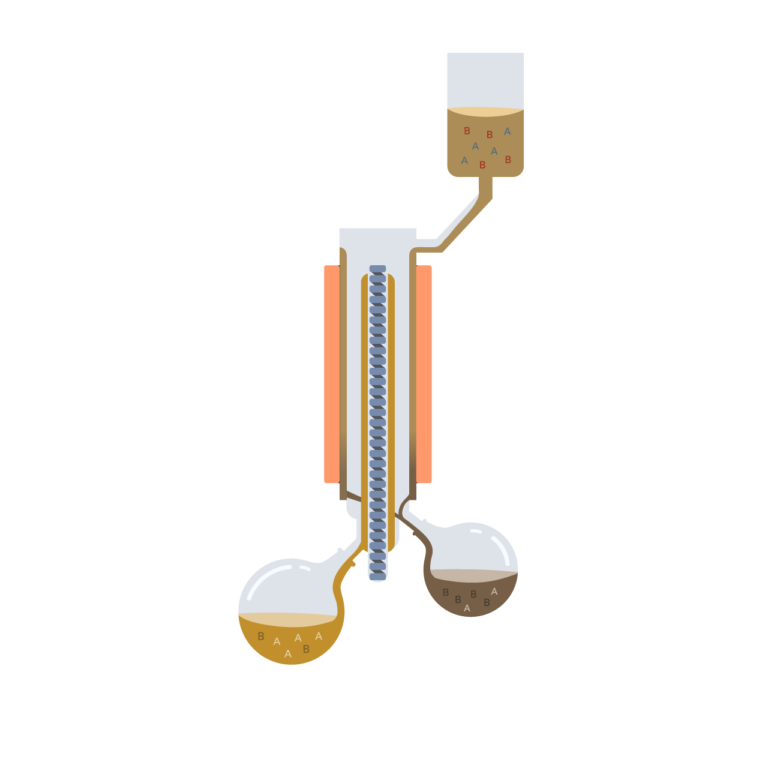

Spinning band can distill THC, CBD, and other cannabinoids at greatly reduced temperatures. The distillation rate also prevents material from staying at temperature for extended periods of time. Above certain temperatures or after many hours of being hot, isomerization can occur. Wiped film manufacturers would have you believe cannabinoids degrade easily with time exposure to […]

CBN and Cannabis Oil Extracts

by brblogCBN is a cannabinoid that is less psychoactive than THC. It is an oxidized form of THC that is known for its sedative effects. We get many questions about the presence of CBN in distilled oil. CBN naturally occurs in cannabis. Typical concentrations in refined oils are 1.5% or less . Concentrations of 4% or more […]

Vacuum grease B/R spinning band systems are equipped with o-ring joints. O-ring joints are awesome! They make vacuum tight seals without the use of vacuum grease.Finding vacuum leaks is time consuming and frustrating. O-ring joints make such good seals that having a vacuum leak will be rare. The o-ring sits in a polished grove on the male […]

Short path and wiped film distillation systems use connections called taper joints that require vacuum grease in order to make a vacuum tight seal. Taper joints also have the tendency to seize up! Pulling two pieces of stuck glass apart can be a nerve wracking task. Taper joints also make these distillation systems prone to […]

Ethanol for Easy Cannabis Oil Handling

by brblogEthanol for easy and complete cannabis oil transfer Extracted oil is viscous and sticky. It requires heating in order to transfer it and valuable residue left behind in the original container. If you have ever run a rotovap, you will know the last bit of solvent always takes the longest to remove. The oil gets […]

Scalable B/R Cannabinoid distillation systems offer a selection of boiling flask sizes to fit your needs. Choose from 3, 5, 12, 22 and 50 liter sizes. The distillation system can grow along with your company. Upgrade to larger boiling flasks or move up to a higher throughput spinning band distillation column as business expands (ask […]

Cleaning a B/R spinning band distillation system couldn’t be easier. Just distill some ethanol to dissolve any residue left behind in the boiler, distillation column, fraction collector and receivers. No need to disassemble the distillation column in order to clean. For cleaning after a run, just load a boiling flask with ethanol, launch the automatic […]

Wiped film (WF) distillation is intended to be operated as a continuous process. Continuous processes have the advantage of running nonstop. Oil is fed in one end and product comes out the other end. But wiped film for cannabis oil is being operated as a multi stage batch process which is on the other end […]

Recent cannabis-distillation Posts

NIR Measurement of Cannabinoid Decarboxylation

by Luke on May 19, 2021

NIR to Monitor CBD to Delta-8 Conversion

by Luke on May 19, 2021

GMP for Cannabis and Hemp Oil Distillation

by Paul on April 16, 2020

Removing Water Soluble Components from Cannabis Oil

by Luke on April 10, 2020

Color of Bulk Distillate : Why is it so dark?

by Luke on March 25, 2020

Questions?

Contact us for more information on our products and services.