Distillation Rates Comparison

by brblogHow do different methods of distillation stack up against each other? System (Size) Distillation Rate Liters of Distillate Number of Passes Final Purity Total Time Short Path 1 (Average) 0.5 L/hr 10 L 2 90% 40 Hours Short Path 2 (Large) 1 L/hr 10 L 2 90% 20 Hours Wiped Film 1 (Average) 0.75 […]

Wiped Film and “The Split”

by brblogDid you know that during a decent first pass in a wiped film that 50% of your starting material can go to waste? The 50/50 split is the perfect example of the low-efficiency of a wiped film. If your crude extract is 50-70% cannabinoids, then how can 50% of the material be waste on the […]

Short Path Distillation Short path distillation is an introductory distillation technique sometimes used in labs in their start up phase. Short path produces usable but lower quality oil often in the 80% cannabinoid range after 2-3 passes. A common problem during short path operation are vacuum leaks which lead to degradation and dark oil. Spinning […]

Cannabis Oil Extraction – Crude Oil Extraction Consumption of cannabis has shifted over the years from smoking the plant to the use of concentrated cannabinoid oils. Vaping, dabbing, and edibles are becoming the most popular ways to use cannabis oil. These oils which are rich in THC and CBD are made by extracting the cannabinoids […]

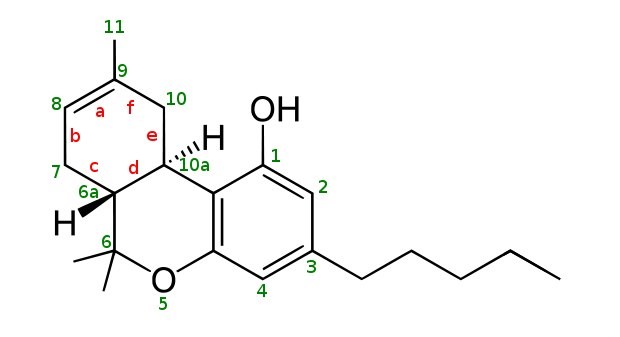

THC Oxidation to CBN CBN is the oxidative degradation product of THC. It is more stable than THC due to its conjugated structure. THC- Delta 9 CBN […]

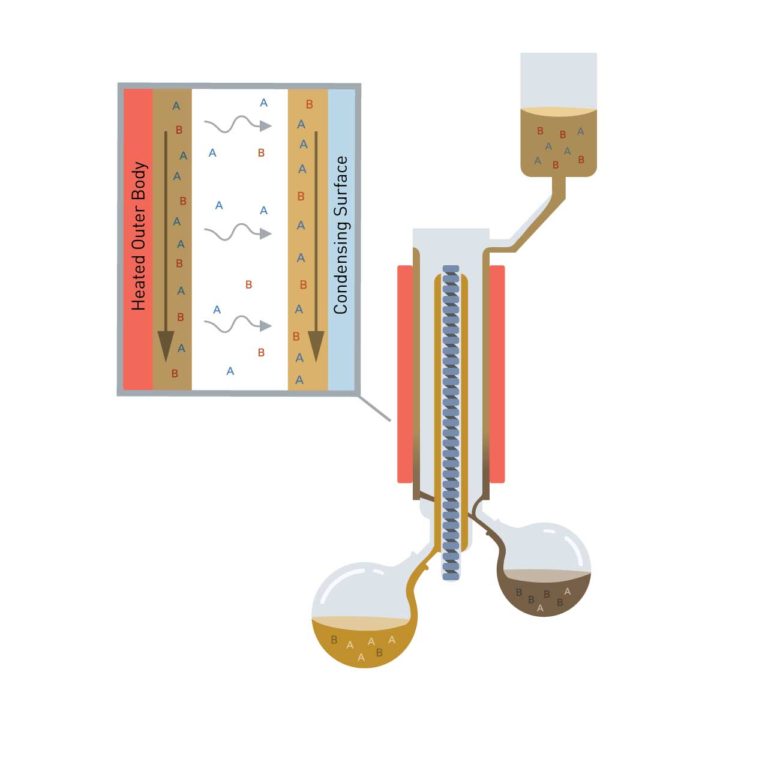

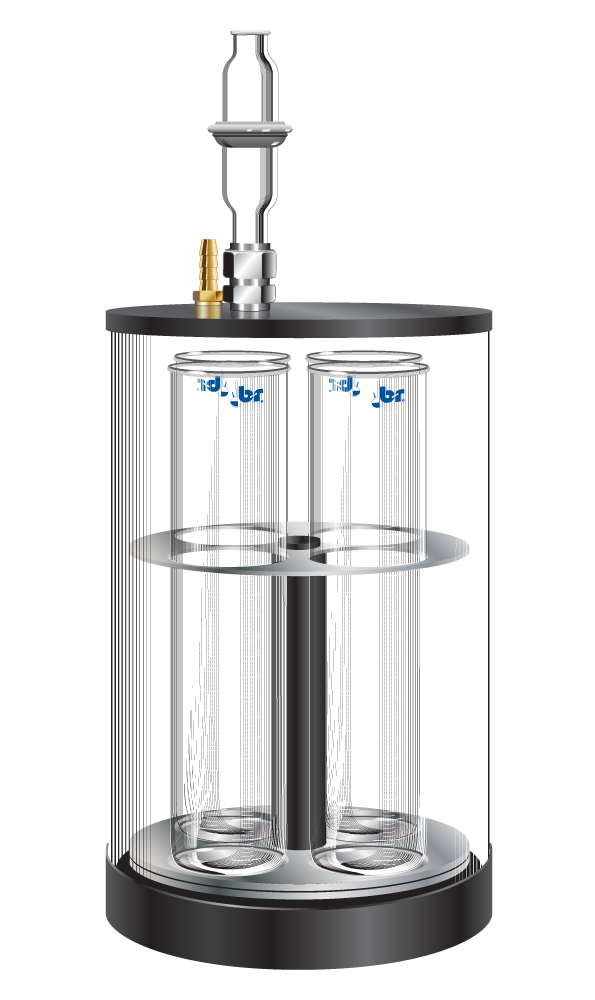

Spinning Band Distillation Spinning band distillation offers a high efficiency distillation column that can produce 90+% cannabinoid distillate in a single pass. A single pass distillation means you’ll spend a lot less time distilling. Operation is streamlined. The spinning band acts as dynamic packing. Condensed oils are pumped back down the column while pure vapors rise […]

Spinning band distillation separates the cannabis oil extract according to the boiling points of the components. Mono-terpenes have the lowest boiling points, so they are collected first. They can be found in the cold trap receiver due to their low boiling points. Residual ethanol is collected next in the fraction collector followed by the higher […]

Those “things” near bottom of the spinning band distillation column are called bellows. They function as a flexible expansion joint. Glass is normally anything but flexible and these bellows are engineered to allow the expansion and contraction over the length of the column. Distillations start at room temperature and goes up to the distillation temperature […]

The spinning band distillation column has a vacuum jacket (like a thermos) to minimize heat loss through the distillation column wall. The evacuated jacket disrupts heat conduction due to the lack of air (only 10-7 mmHg !). The vacuum jacket has a silver coating on the inside to reflect any radiant heat. Combined with the […]

Spinning band distillation Spinning band distillation can produce distillate with very high THC/CBD concentrations. Over 90% THC concentration is typical for a first pass. Some customers are routinely producing 98%+ cannabinoid distillates! How does the spinning band do it? Distillation separates components by their boiling points. This is commonly referred to as the “efficiency” of […]

Recent cannabis-distillation Posts

NIR Measurement of Cannabinoid Decarboxylation

by Luke on May 19, 2021

NIR to Monitor CBD to Delta-8 Conversion

by Luke on May 19, 2021

GMP for Cannabis and Hemp Oil Distillation

by Paul on April 16, 2020

Removing Water Soluble Components from Cannabis Oil

by Luke on April 10, 2020

Color of Bulk Distillate : Why is it so dark?

by Luke on March 25, 2020

Questions?

Contact us for more information on our products and services.